El equipo de herramientas de chapa metálica es el equipo de producción básico de la industria de procesamiento de chapas, y ocupa una posición importante en el campo de la conformación de productos metálicos. Las máquinas herramienta de corte de metales en el proceso anterior del tratamiento de chapas ya se han automatizado en su mayoría, pero la gran mayoría de los equipos de doblado en el campo de las chapas sigue siendo equipamiento tradicional, con baja automatización, baja eficiencia productiva y altos requisitos técnicos para los operadores.

Las principales ventajas del centro de doblado flexible e inteligente en comparación con las prensas tradicionales son las siguientes:

1. La velocidad del centro de doblado flexible e inteligente

En el proceso de doblado es completamente automático hasta 0,2 segundos/herramienta, lo que reduce considerablemente el tiempo de ciclo del doblado multilateral y multipasivo, más de tres veces más rápido que la prensa CNC tradicional; cuanto más plegados y más complejo sea el trabajo, mayor será la ventaja de velocidad.

La máquina de doblado CNC tradicional requiere trabajadores técnicos para sostener la pieza en posición, doblarla y reubicarla después de cada pliegue, lo que resulta en una baja eficiencia.

2.Artificial

El centro de doblado flexible inteligente tiene bajos requisitos técnicos para los trabajadores; los operarios comunes pueden ser entrenados para trabajar, sin necesidad de contratar trabajadores experimentados, mientras que el proceso de doblado es completamente automatizado, ahorrando mucho trabajo y reduciendo considerablemente la intensidad laboral. En el caso de las piezas de mayor tamaño, la máquina de doblado CNC tradicional a menudo requiere más de una persona para completar la tarea, mientras que el centro de doblado flexible inteligente solo necesita que los trabajadores coloquen la pieza en la mesa de trabajo, y el equipo realiza automáticamente la ubicación, ahorrando tiempo y esfuerzo.

3.Seguridad

El centro de doblado flexible inteligente no requiere que los trabajadores sostengan manualmente la pieza, ya que el proceso de doblado es completamente automatizado, lo que reduce considerablemente los riesgos de seguridad causados por errores de los trabajadores.

4.Facilidad de uso

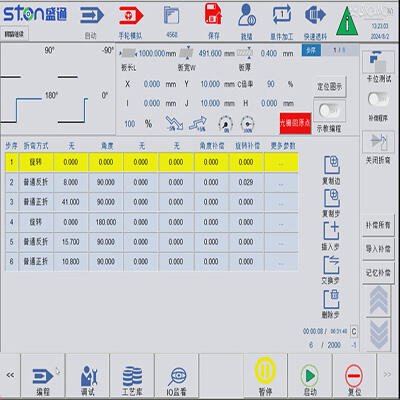

centro de doblado flexible e inteligente que utiliza programación visual gráfica, los trabajadores solo necesitan introducir los datos de doblado según la pieza, el sistema genera automáticamente las instrucciones de doblado, sin necesidad de usar programación con código, un trabajador común puede dominarlo en 2 horas. El centro de doblado CNC tradicional requiere que los trabajadores dominen habilidades de programación complejas y memoricen el orden de doblado de cada pliegue en el proceso de doblado, lo cual es difícil y tiene una alta tasa de errores.

5. Consistencia

El centro de doblado flexible e inteligente puede realizar el posicionamiento automático de la placa, la precisión de posicionamiento del sistema es alta, la consistencia del producto después de la formación es mayor, más adecuada para la producción en masa. La precisión de posicionamiento del centro de doblado CNC tradicional no es alta, lo que puede causar errores dimensionales debido al posicionamiento múltiple.

6. Automático

El centro de doblado flexible e inteligente cuenta con una amplia gama de interfaces, lo que facilita la conexión con líneas de producción aguas arriba y aguas abajo. El brazo robótico puede conectarse para realizar cargas y descargas automáticas. Con el mismo sistema de control del brazo robótico autónomo y el centro de doblado flexible e inteligente, la eficiencia colaborativa es mayor; al reemplazar la pieza no es necesario mantener dos conjuntos de procedimientos, solo cambie el programa del centro de doblado, que generará automáticamente el programa del brazo robótico, ofreciendo mayor flexibilidad.

No solo tiene ventajas significativas a nivel técnico, sino que también puede satisfacer mejor la demanda del mercado, mejorar la eficiencia de producción y reducir los costos de producción. En el futuro, con el desarrollo continuo de la industria manufacturera y el progreso tecnológico, el rango de aplicación del centro de doblado flexible inteligente se expandirá aún más, y su posición en la industria manufacturera será más estable. Al mismo tiempo, esto también impulsará el desarrollo de toda la industria manufacturera hacia una dirección más eficiente, inteligente y sostenible.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

IS

IS

AZ

AZ

EU

EU

KA

KA

BN

BN

LO

LO

LA

LA

MN

MN

NE

NE