মডেল:STON-A1,B1

আনুমানিক ম্যাক্স বেঞ্জিং লেংগ্থ: ১০০০~১৪০০মিমি

আনুমানিক ম্যাক্স বেঞ্জিং টিন্কনেস:এসএস ১.২মিমি, সিআরএস ২.০মিমি, এল ২.৫মিমি, সিএস ১.২মিমি

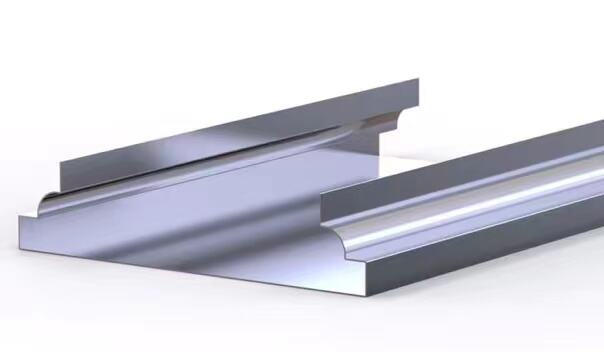

১. আর্ক বাঁকানো: ন্যूনতম ব্যাসার্ধ ৬mm, ডিকোরেটিভ পার্টস বা আর্ক-আকৃতির গঠনের জন্য ব্যবহৃত (যেমন কার বাম্পার ব্র্যাকেট)

২. ডেড এজ বাঁকানো: বাঁকানোর কোণ ১৮০°-এর কাছাকাছি, বক্স সিলিং গঠনের জন্য ব্যবহৃত (যেমন স্টেইনলেস স্টিলের জল ট্যাঙ্ক)

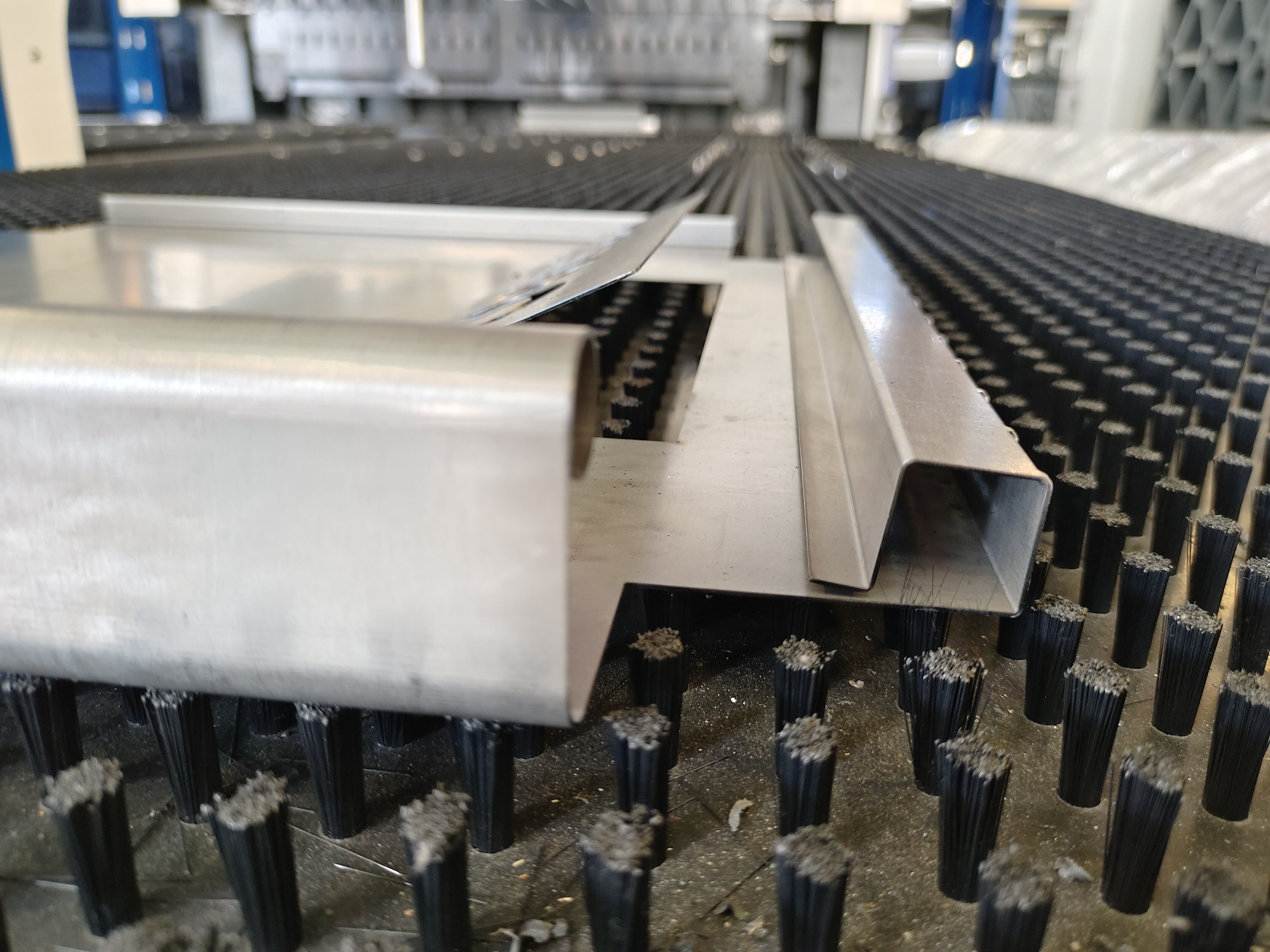

৩. বহু-ধাপের বাঁকানো: প্রোগ্রাম নিয়ন্ত্রণের মাধ্যমে একসাথে বহু বাঁকানোর প্রক্রিয়া (যেমন "Z" ধরনের এবং "U" ধরনের বাঁকানো) সম্পন্ন করা হয় যাতে প্লেট উল্টানোর সংখ্যা কমে

ইনস্টলেশন: এঞ্জিনিয়ারদের সাইটে/রিমোট অনলাইন গাইডেন্স/গ্রাহকদের সাইটে শিখুন

এটি ঐতিহ্যবাহী বেঞ্চ মেশিনের তুলনায় ২৬০% বেশি কার্যকারিতা ধরে, এটি ৬ প্রেস ব্রেকের সমতুল্য

|

STON-A1 |

STON-B1 |

|

|

মাত্রা (দৈ×প্র×উচ) |

2800×1500×2800mm |

3400×2000×2800mm |

|

খাওয়ানোর পদ্ধতি |

শূন্যতা গ্রেপ্টিং |

শূন্যতা গ্রেপ্টিং |

|

সর্বাধিক বাঁকানোর গতি |

0.2s/knife |

0.2s/knife |

|

সর্বোচ্চ বাঁকানোর দৈর্ঘ্য (মিমি) |

1000×1000 |

1400×1250 |

|

সর্বোচ্চ বাঁকানোর উচ্চতা (মিমি) |

170 |

170 |

|

সর্বনিম্ন বাঁকানোর পুরুত্ব (মিমি) |

0.15 |

0.15 |

|

ন্যূনতম চার-পাশের আকৃতির সাইজ (মিমি) |

140×140 |

160×190 |

|

এক-পাশের আকৃতি তৈরি |

১৪০ মিমি |

১৬০মিমি |

|

সর্বাধিক বাঁকানোর বেলুনি (মিমি) |

রুঢ়ালোহ 1.2 আয়রন প্লেট ২.৫ অ্যালুমিনিয়াম প্লেট ২.৫ |

স্টেইনলেস স্টিল ১.৫ আয়রন প্লেট ২.৫ অ্যালুমিনিয়াম প্লেট ২.৫ |

|

|

|

|

অনেকগুলি ধাপে বাঁকানো |

আর্ক বাঁকানো |

ডেড এজ বাঁকানো |

সিলিং স্ট্রাকচার |

| কাস্টিং মেশিন বডি |  |

গ্রস মেশিনিং শেষ হওয়ার পর গুড়ি অংশগুলো খোলা বায়ুতে এজিং ট্রিটমেন্ট দেওয়া হয়, যাতে বিস্তারিতভাবে আন্তরিক চাপ ছাড়ানো হয় এবং সূক্ষ্ম মেশিনিং আগে তারা লম্বা সময় ব্যবহার করা যায় এবং বিকৃতি ছাড়াই থাকে এবং সমগ্র নির্ভুলতা নিশ্চিত করা হয়। |

| গাইড রেল, স্ক্রু রড এবং বেয়ারিং |  |

বিভিন্ন ধরনের যন্ত্রপাতির কাজের প্রয়োজনীয়তার অনুযায়ী বড় ব্যাসার্ধের চূর্ণ গ্রেড স্ক্রু রোড ব্যবহৃত হয়। জাপান থেকে ইমপোর্ট করা এনএসকে/নাচি বেয়ারিং ব্যবহার করা হয় যাতে বেশি ভারবহন ক্ষমতা এবং ট্রান্সমিশন নির্ভুলতা পাওয়া যায়। বড় রোলার গাইড স্লাইডারের উত্তম অধঃক্ষয় পারফরম্যান্স এবং শক্তিশালী ভারবহন ক্ষমতা রয়েছে। এটি যন্ত্রপাতির চালনা স্থিতিশীলতা বাড়ানো এবং সার্ভিস জীবন বাড়ানোর কাজে কার্যকর। |

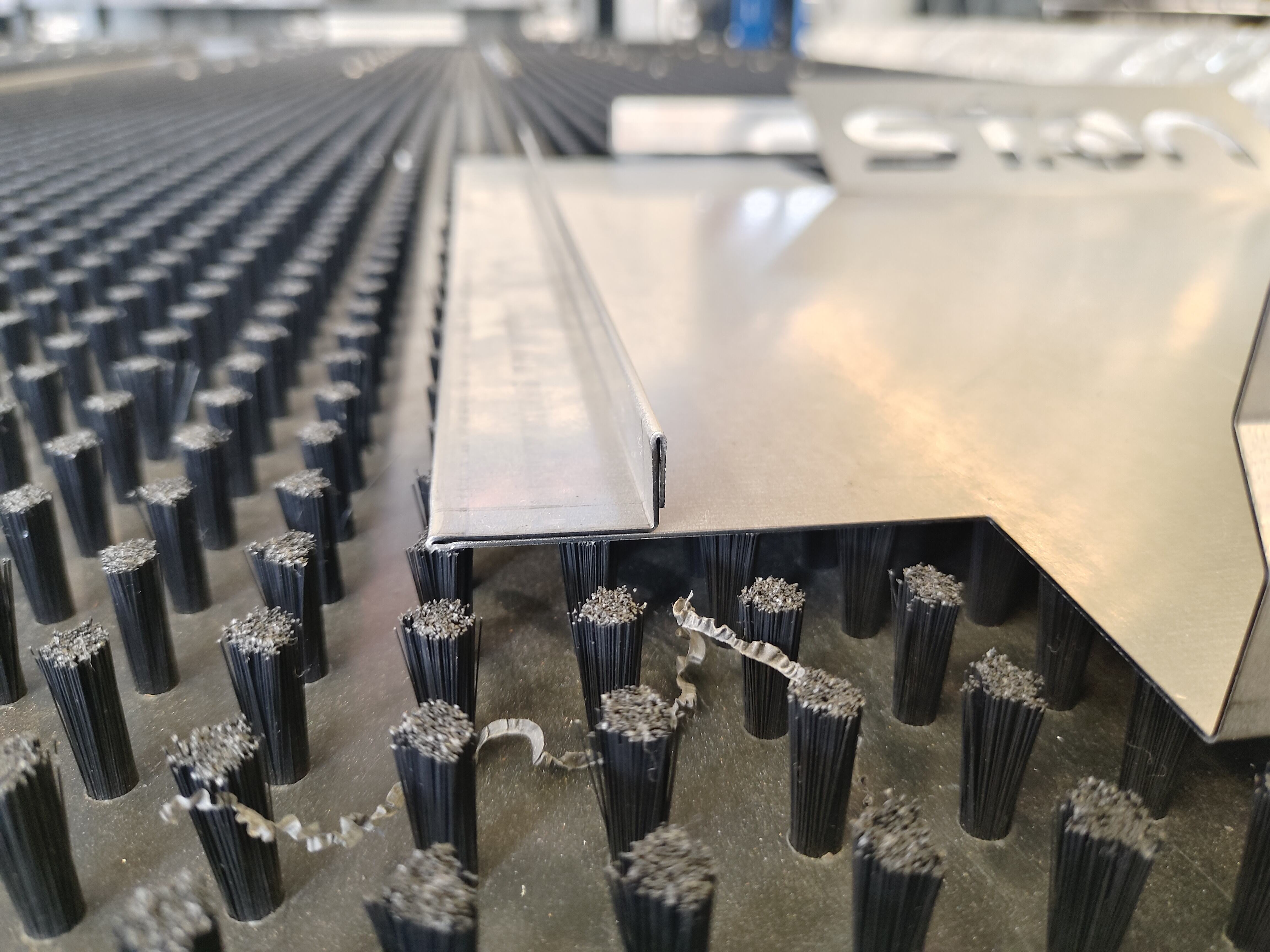

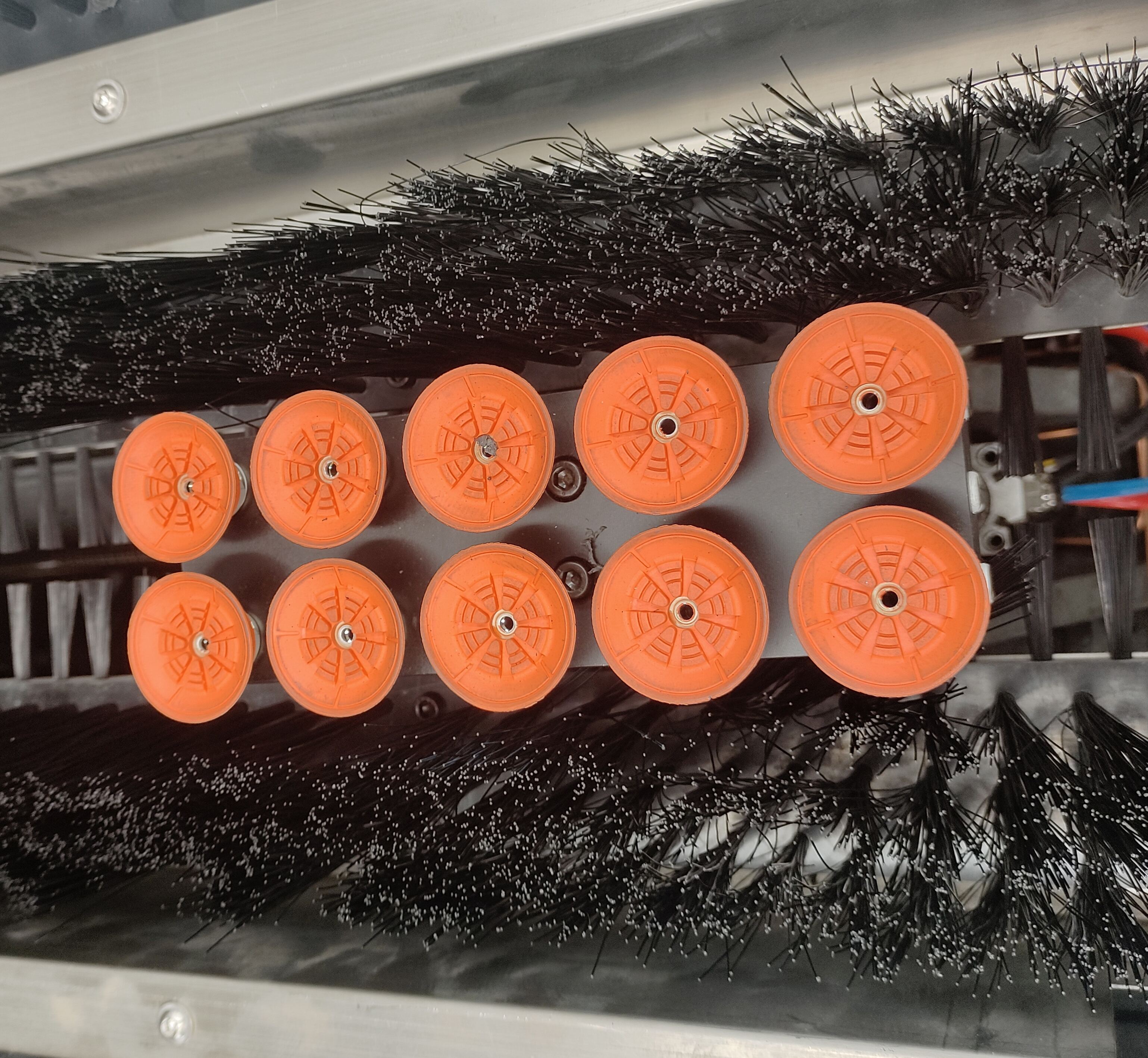

| সাকশন কাপ |  |

STON প্যানেল বেন্ডারের ভ্যাকুম গ্রিপিং সিস্টেম এক জোড়া বিন্দুতে চুইপশন ব্যবহার করে বিভিন্ন শীট আকারগুলিকে নিরাপদভাবে ধরে রাখে, যা ঠিক মেটাতে সাহায্য করে। সিস্টেমটি চাপ ডায়নামিকভাবে পরিবর্তন করে যেন বিভিন্ন উপাদানের মধ্যে বিকৃতি ও ফেলে না যায়। |

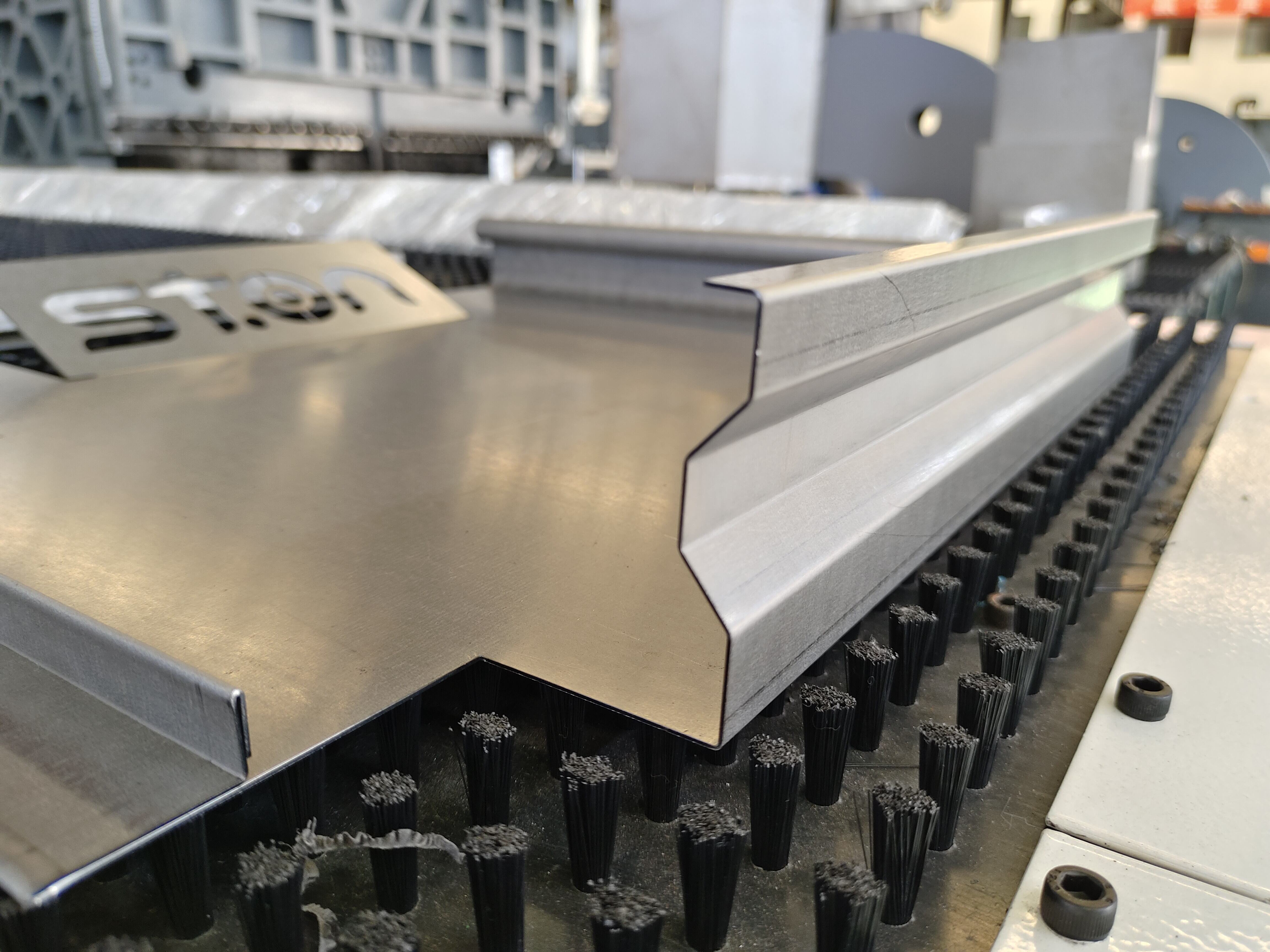

| আপার/লোয়ার প্রেস ছুরি এবং বেঞ্চিং ছুরি |  |

৪২CrMo ফোরজিং মেটেরিয়াল দিয়ে তৈরি এবং এটি সেবা জীবন এবং বেঞ্চিং প্রয়োজনের নিশ্চয়তা জন্য কঠোর রোহ এবং ডেটেইল মেশিনিং, হিট ট্রিটমেন্ট, টেম্পারিং এবং লেজার কুয়াচিং পদক্ষেপ অনুসরণ করে। |

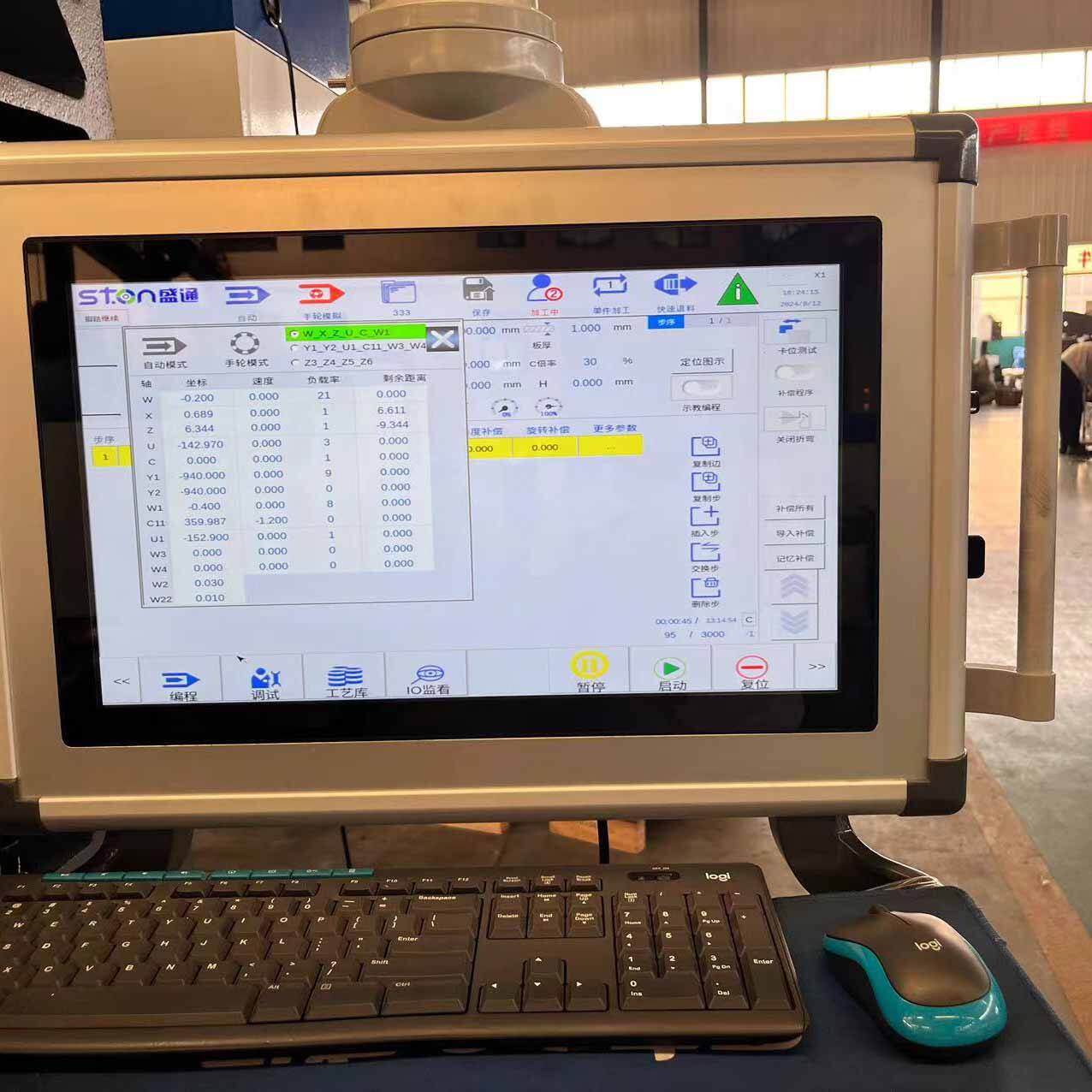

| কন্ট্রোল সিস্টেম |  |

আমদানি করা এলেকট্রিক সার্ভো বন্ধ লুপ নিয়ন্ত্রণ পদ্ধতি অবলম্বন করা হয়েছে, যা 25টি অক্ষের একসাথে লিঙ্ক করতে সমর্থ যা বহু-অক্ষ একই সাথে লিঙ্কের, সুচারু বাঁকানোর চালনা এবং যান্ত্রিক চালনার উচ্চ সহযোগিতা সফলভাবে অর্জন করে। ট্রাস লোডিং/আনলোডিং পরিষক্তি এবং ম্যানিপুলেটরের জন্য নিয়ন্ত্রণ পদ্ধতির জন্য সংযোগ পোর্ট সংরক্ষিত আছে, যাতে ব্যবহারকারীরা তাদের প্রয়োজন অনুযায়ী বিভিন্ন ব্র্যান্ডের ম্যানিপুলেটর এবং ট্রাস লোডিং/আনলোডিং পরিষক্তি সংযুক্ত করতে পারেন। |

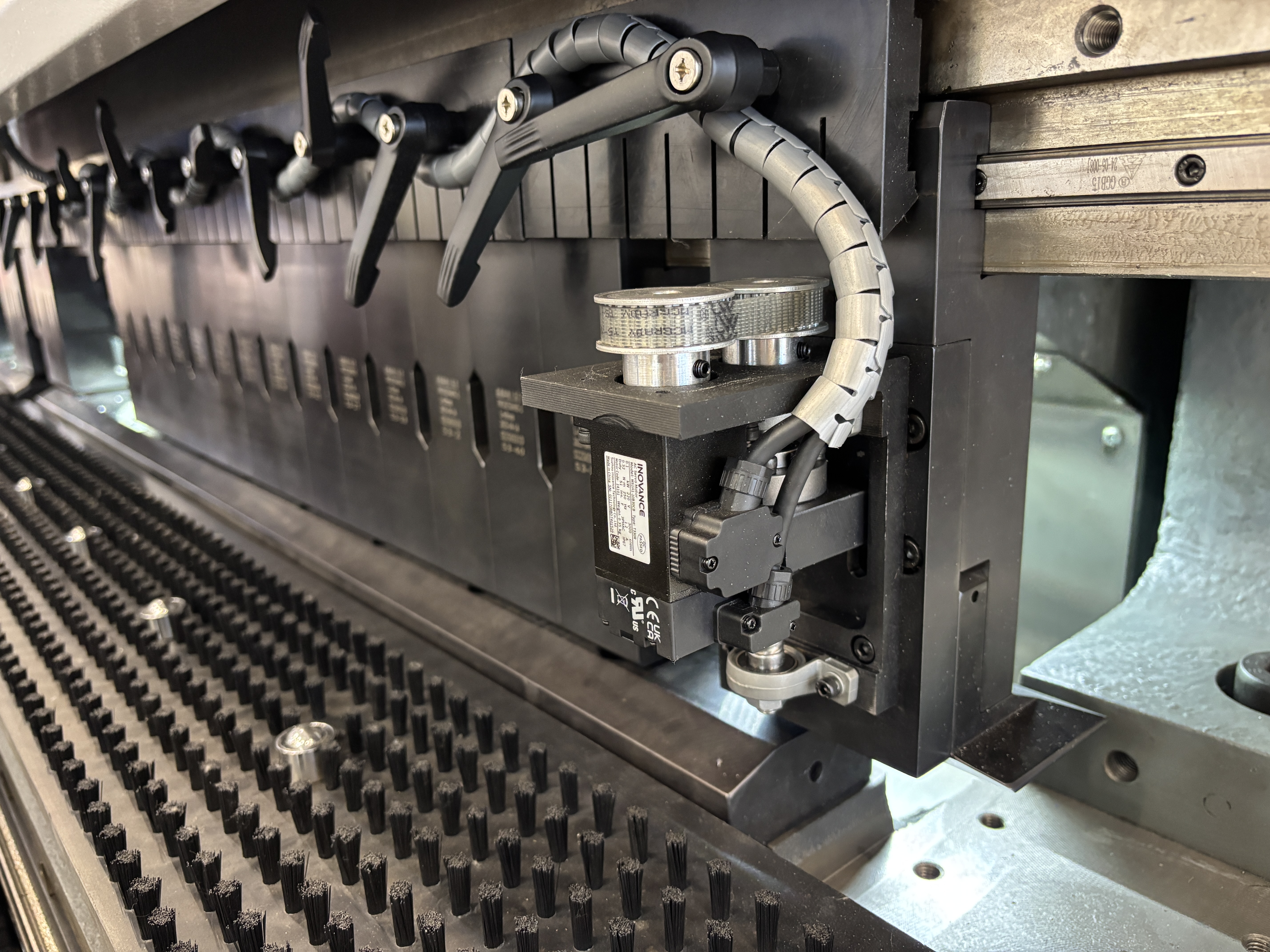

| সার্ভো মোটরস |  |

আসল বাঁকানো টর্ক এবং বিভিন্ন ব্যবহারকারীদের প্রয়োজনের উপর ভিত্তি করে আমদানি/ঘরোয়া সার্ভো মোটর নির্বাচন করা হয়। সার্ভো মোটরের সিগন্যাল বাস মাধ্যমে প্রেরণ করা হয় এবং নিয়ন্ত্রণ পদ্ধতি ব্যবহার করে বন্ধ লুপ নিয়ন্ত্রণ অর্জিত হয়। এটি সিগন্যাল প্রেরণের বাস্তবকালীন পর্যবেক্ষণ নিশ্চিত করে এবং সিগন্যাল হারিয়ে ফেলা এবং অনুভব্য না হওয়া সিগন্যাল প্রেরণ এড়িয়ে যায়। |

| বৈদ্যুতিক উপাদান |  |

আমদানি বিদ্যুৎ উপকরণ ব্যবহার করা হয়েছে যা নিয়ন্ত্রণ সিস্টেমের স্থিতিশীলতা নিশ্চিত করে; বিদ্যুৎ আলমারিতে দেশজ বিখ্যাত ব্র্যান্ডের এয়ার কন্ডিশনার লাগানো হয়েছে যা আলমারিতে তাপ ছাড়াতে সাহায্য করে। |

| UNIQUE DISTURBANCE COMPENSATION DESIGN |  |

বিশেষ ব্যাঘাত পূরণের ডিজাইনটি বিভিন্ন দৈর্ঘ্য, বিভিন্ন প্লেট মোটা এবং বিভিন্ন উপাদানের বাঁকানো কোণ এবং সরলতা পূরণের সমস্যা সমাধান করতে ব্যবহৃত হয় যাতে কাজের বস্তুর কোণ এবং সরলতা সহনশীলতা সর্বনিম্ন পরিসরের মধ্যে কার্যকরভাবে নিয়ন্ত্রিত হয়। |

| হ্যান্ড ওয়ীল |  |

এই ডিজাইনটি কাটারের অবস্থান ও সঠিকতা পরীক্ষা করতে আরও সুবিধাজনক করে। সিস্টেম নিয়ন্ত্রণের সময় ভুল চালানির কারণে টুল ও সরঞ্জামে ক্ষতি এড়ানো যায় এবং বেঞ্চ পরীক্ষার প্রক্রিয়ায় অপচয় কমে। |

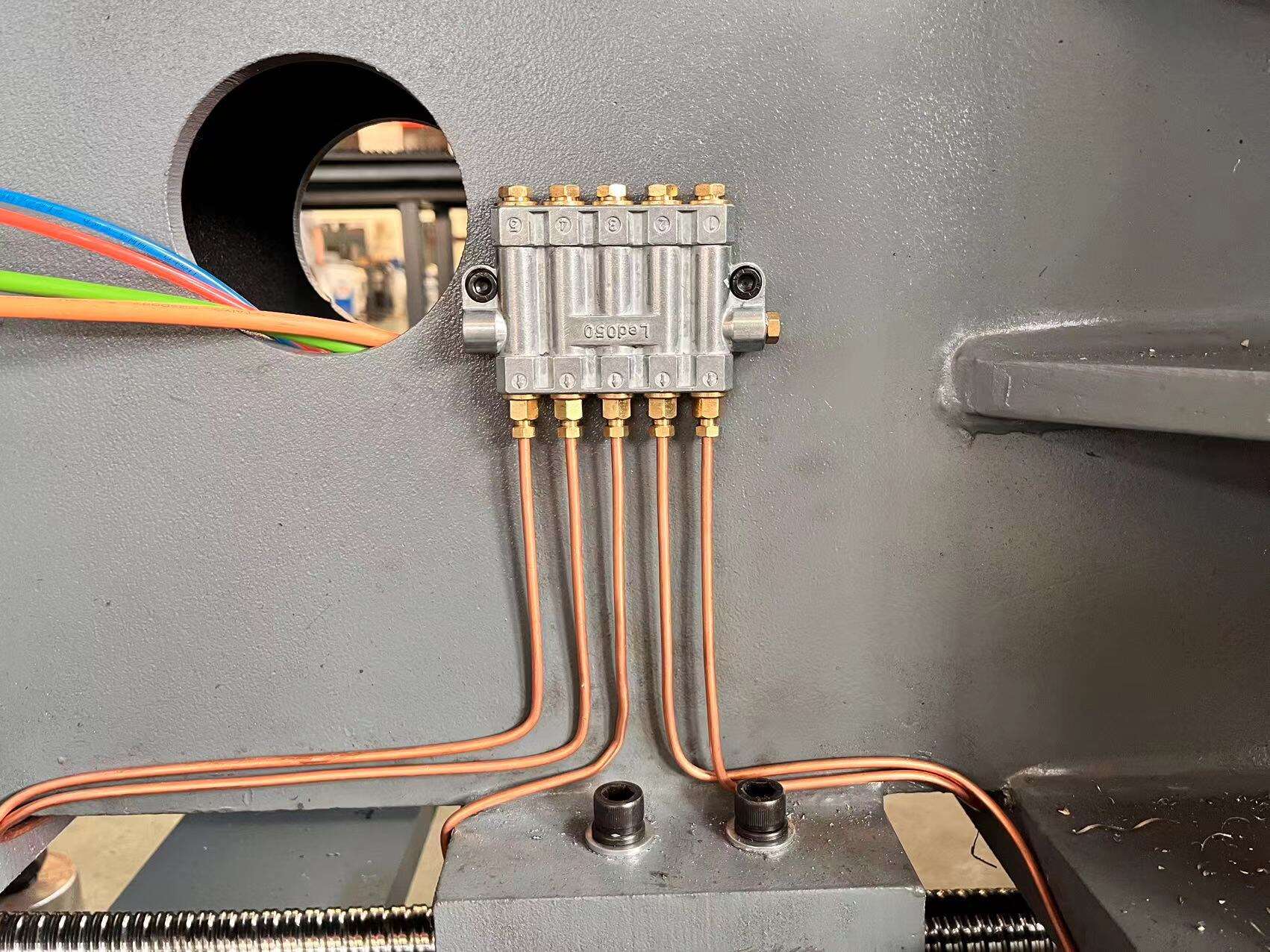

| চর্বি প্রণালী |  |

অটোমেটিক লুব্রিকেশন সিস্টেম নিশ্চিত করে যে চলমান অংশগুলি সময়মতো লুব্রিকেটেড হবে, এবং তেল ও লুব্রিকেশনের অভাবে স্ক্রু রড বল এবং গাইড রোলারের মোচড় প্রতিরোধ করে এবং স্ক্রু রড এবং গাইড রেলের জীবনকাল বাড়ায়। অন্যান্য সাপ্লাইয়ারদের দ্বারা সাধারণত ব্যবহৃত প্লাস্টিকের পাইপলাইনের তুলনায়, আমাদের সরঞ্জাম কাপার লুব্রিকেশন পাইপলাইন ব্যবহার করে প্লাস্টিক পাইপলাইনের বৃদ্ধি এবং ফেটে যাওয়ার ঝুঁকি দূর করে। |

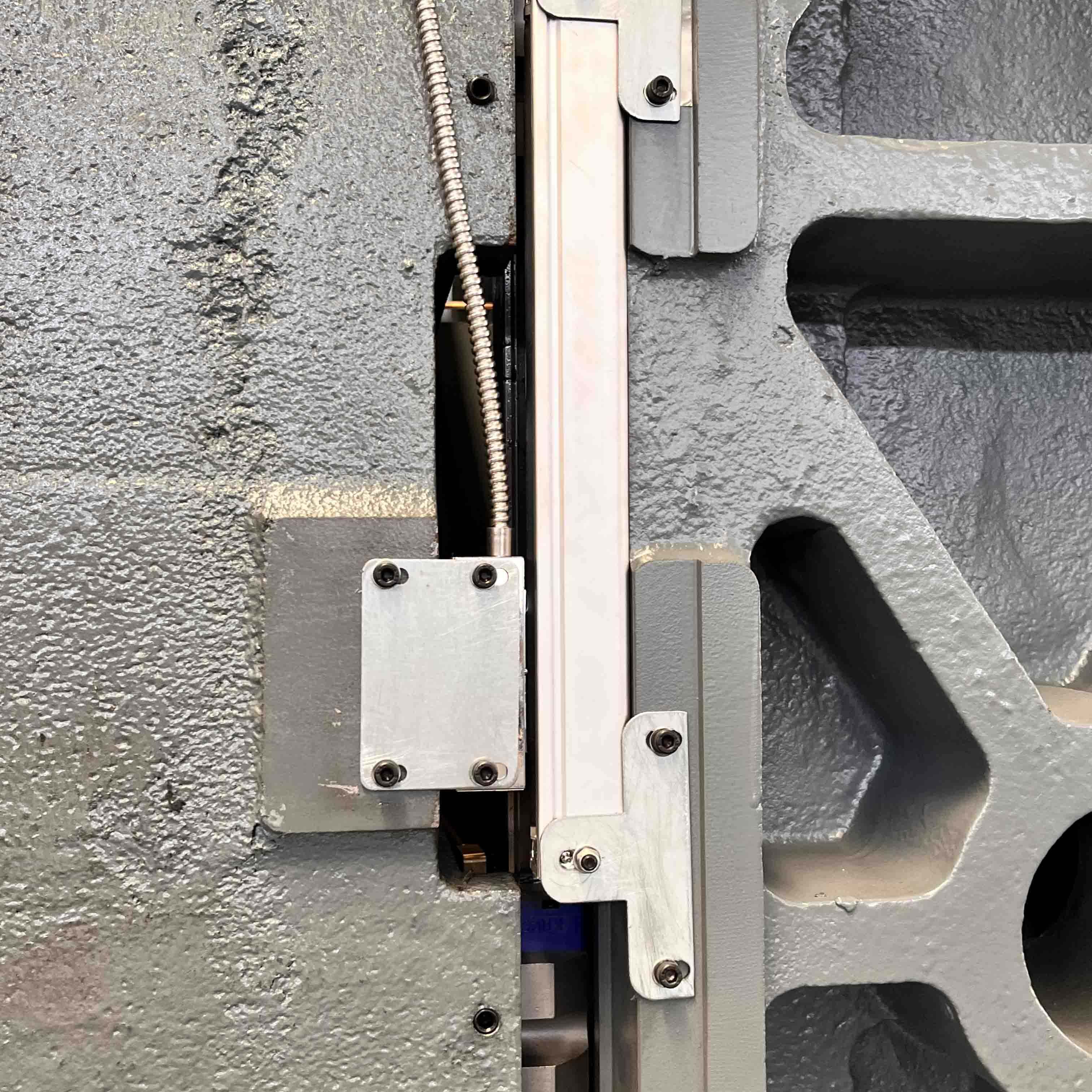

| GRATING RULER DETECTION |  |

অনুপ্রস্থ ভার পরীক্ষা সিস্টেম, যান্ত্রিক/কাজের বস্তুকে কার্যকরভাবে সুরক্ষিত রাখে এবং কাজের বস্তুর অপচয় কমায়। |

| .BLANK HOLDER(OPTIONAL) |  |

অন্যান্য কোম্পানিগুলি যে গ্রেভিটি হিঙ্গ কাটার ব্যবহার করে তার তুলনায় শেনটোং মেশিনগুলি ইলেকট্রিক নিয়ন্ত্রিত হিঙ্গ কাটার ব্যবহার করে, যা কাজ করার সময় হিঙ্গ কাটার যখন কাজের বস্তুর সাথে স্পর্শ করে এবং ছাড়ে তখন কাজের বস্তুর ক্ষতি কমাতে পারে। |

| HORN BLANK HOLDER (OPTIONAL) |  |

জটিল বাঁকানোর প্রক্রিয়ার জন্য সহায়ক ছুরি যুক্ত করা যেতে পারে যেন বিভিন্ন বাঁকানোর প্রয়োজন পূরণ হয়। |

| সি অক্ষ উপরে/নিচে (ওপশনাল) |  |

যখন কাজের টুকরোগুলি নিচে ভাঙার প্রয়োজন হয়, C অক্ষ U অক্ষের সাথে যৌথভাবে কাজ করে এবং কাজের টুকরোগুলি তুলতে সাহায্য করে, ফলস্বরূপ টুকরোগুলি পুনরায় নিয়ে আসার সময় এদের ক্ষতিগ্রস্ত হওয়ার ঝুঁকি কমে। |

আপনি কি একটি ট্রেডিং কোম্পানি না তৈরি করে?

আমরা ফ্যাক্টরি, তাই আমাদের প্রতিদ্বন্দ্বিতামূলক মূল্য আছে এবং আমাদের নিজস্ব বিদেশি বাণিজ্য দল আছে তাই আমরা সহায়তাও দিই।

2. গড় লিড টাইম কত?

স্যাম্পলের জন্য প্রথম সময় ৭ দিন পর্যন্ত। মাস উৎপাদনের জন্য ডিপোজিট পেমেন্ট পাওয়ার পর সময় ৪৫-৬০ দিন।

আপনি কি একটি ODM না OEM ফ্যাক্টরি?

হ্যাঁ, আমরা ODM, আপনি আমাদের আপনার প্রয়োজন পাঠাতে পারেন তারপর আমরা আপনার জন্য ডিজাইন করতে পারি।

4. আপনি কী ধরনের পেমেন্ট পদ্ধতি গ্রহণ করেন?

আপনি আমাদের ব্যাঙ্ক অ্যাকাউন্টে পেমেন্ট করতে পারেন, ওয়েস্টার্ন ইউনিয়ন বা পেপেই: ৩০% এডভান্স ডিপোজিট, B/L এর কপি বিরুদ্ধে ৭০% ব্যালেন্স।

আপনি কি বিদেশে পরবর্তী বিক্রয় সেবা এবং ইনস্টলেশন এবং কমিশনিং সেবা প্রদান করেন?

হ্যাঁ, আমরা পারি। যখন মেশিনটি গ্রাহকের স্থানে পৌঁছাবে, তখন কোম্পানি তাদের পূর্ণ-সময়ের কর্মচারীকে পাঠাবে ইনস্টলেশন এবং কমিশনিং করতে এবং অপারেটরদের প্রশিক্ষণ দেওয়া হবে যতক্ষণ না তারা নিজেদের জন্য মেশিনটি চালাতে পারে।

৬. আমাদের কাছ থেকে আপনি কি কিছু কিনতে পারেন?

CNC Turret Punch Press, CNC bending machine, Fiber Laser Cutting Machine, Bending Automation, Flexible Manufacturing System, Panel Bender এবং শীট প্লেট অটোমেটিক প্রডাকশন লাইন।

৭. আমরা কি সেবা প্রদান করতে পারি?

স্বীকৃত ডেলিভারি শর্ট: FOB, CFR, CIF, EXW;

স্বীকৃত পেমেন্ট মুদ্রা: USD, EUR; RMB

গ্রহণযোগ্য ভালো ধরন: T/T, L/C;