Intelligent bending center is a highly automated intelligent device , which can achieve high accuracy ,high efficiency and high-quality bending of various materials. It mainly composed of a control system,a servo motor , a bending mold and a material sensor. It is a new generation of automatic multilateral bending center, is a new product of sheet metal bending into fully automated production, flexible bending center bending without mold, can fold right Angle, non-right Angle, arc, up and down folding and other combinations of complex shapes, a positioning, to complete multilateral bending, used in different industries of different workpiece metal forming field. At present, the flexible bending center is gradually replacing the CNC bending machine.

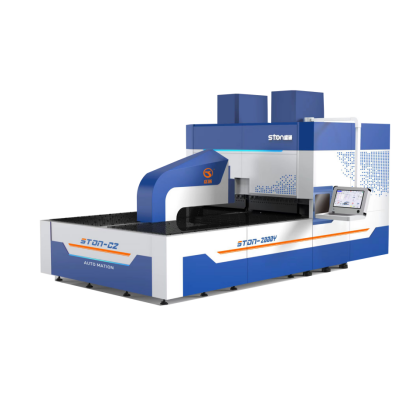

Flexible bending center component

The flexible bending center is composed of control system, operating system, reducer, servo drive, screw, guide rail, bearing, negative pressure pump, fuselage, feed frame, upper and lower bending knives, hinge knives, pneumatic accessories, suction cups, couplings, oil circuit and other systems.

Flexible bending center has been widely used in kitchenware, ventilation, air conditioning, file cabinets, electrical cabinets, tool cabinets, environmental purification and other industries, more and more people choose flexible bending center.

The main advantages of the intelligent flexible bending center compared with the traditional bending machine are as follows: 1, the speed of the intelligent flexible bending center in the bending process is fully automated up to 0.2 seconds/tool, greatly reducing the cycle time of multilateral and multi-channel bending, which is more than 3 times the speed of the traditional CNC bending machine, the more folds and the more complex the workpiece, the greater the speed advantage. Traditional CNC bending machine requires technical workers to hold the workpiece positioning, bending, each fold needs to be repositioned, the efficiency is low. 2, artificial intelligence flexible bending center has low technical requirements for workers, ordinary workers can be trained to work, no need to hire experienced skilled workers, while the bending process is completely automated, greatly saving labor, greatly reducing the labor intensity of workers. The traditional CNC bending machine for the larger size of the workpiece, often need more than one person to complete, and the intelligent flexible bending center only needs workers to place the workpiece to the workbench, and the equipment automatically completes the positioning, which is a real time-saving and labor-saving.

Main Technical Parameters

| STZ03-A2 | STZ03-B1 | STZ03-B1 | STZ03-B2 | STZ03-C2 | STZ03-D2 | STZ03-E2 | |

| Max. bending speed | 0.2s/knife | 0.2s/knife | 0.2s/knife | 0.2s/knife | 0.3s/knife | 0.5s/knife | 0.6s/knife |

| Max. bending length (CM) | 100*100 | 140*125 | 140*125 | 160*125 | 200*150 | 250*150 | 320*150 |

| Max. bending height (mm) | 170/210 | 170/300 | 170/300 | 170/300 | 170/300 | 170/300 | 170/210 |

| Feeding method | Press arm type | Suction cup type | Press arm type | Press arm type | Press arm type | Press arm type | Press arm type |

| Feeding table | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball |

| Lubrication pipeline | Copper pipe | Copper pipe | Copper pipe | Copper pipe | Copper pipe | Copper pipe | Copper pipe |

| Min. bending thickness (mm) | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Min. four-sided forming size | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm |

| Single-sided forming | 150mm | 150mm | 150mm | 150mm | 150mm | 150mm | 150mm |

| Hinge knife | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Advanced command | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Arc command | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Replacement of suction cup assembly width | Standard | ||||||

| Suction cup group lifting | Optional | ||||||

| Press foot lifting | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

| C-axis lifting | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Automatic lubrication function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Bias load detection function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Bias load follow-up function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Plate thickness detection function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Automatic feeding interface | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| High speed control module | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Flattening function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| up/down pressed dead edge | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Knife adjustment device | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| hand wheel | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Cloud-based management function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Rated voltage | 380V | 380V | 380V | 380V | 380V | 380V | 380V |

| Max.bending.thickness (mm) | Stainless steel 1.0 Cold plate 1.2 Aluminum plate 1.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 |

| Dimensions (CM) | L* W *H 310 * 150 * 280 | L* W *H 350 * 200 * 280 | L* W *H 450 * 200 * 280 | L* W *H 450 * 250 * 280 | L* W *H 510 * 270 * 280 | L* W *H 570 * 310 * 280 | L* W *H 700 * 380 * 280 |

Main configuiation

| No. | Name | Supplier/Brand |

| 1 | Control system | Imported brand |

| 2 | Servo motor, drive | Imported/domestic servo |

| 3 | Cast body | Xuchang, Henan |

| Welded body | Qingdao Shengtong | |

| 4 | Feeding rack | Qingdao Shengtong |

| 5 | Reducer | Taiwan Dingrui/ROUIST |

| 6 | Screw rod | Nanjing Technical Equipment/Shaanxi Hanjiang |

| 7 | Guide rail | Nanjing Technical Equipment/ROUIST |

| 8 | Bearing | Japan NSK/NACHI |

| 9 | Negative pressure pump | Zhejiang Tengyuan (Press arm type excluded) |

| 10 | Electrical parts | Schneider, Omron |

| 11 | Grating ruler | Suzhou SINO |

| 12 | hand wheel | Taiwan FUTURE |

| 13 | Machine air conditioning | Tongfei Refrigeration |

| 14 | Pneumatic accessories | Taiwan AirTAC |