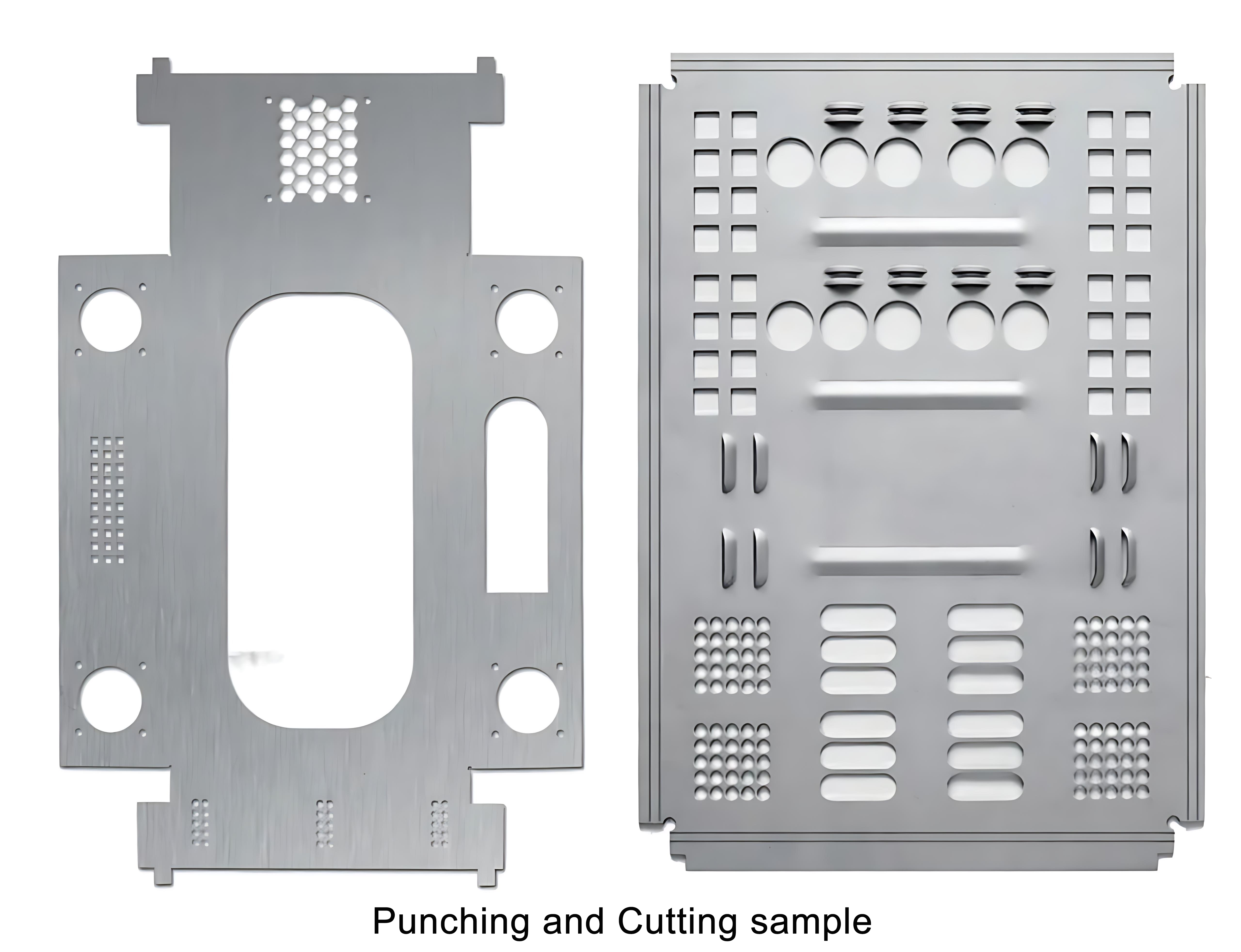

1.Model:SFL30125/SFL30150/SFL40125

2.Provides 25/30/40 tons of punching force,1250/1500/2000/2300mm optional

3.Max punch thickness:CS 3mm,MS 4mm, SS 3mm, GI 4mm,AL 6mm

4.The material utilization rate reaches 90% to 95%, which greatly reduces the waste of sheet materials

5.The process flow is simplified, and punching, forming, contour cutting, tapping and other processing can be completed in one programming

6.The noise pollution is small, and the stamping and laser cutting processes are reasonably allocated to optimize the processing technology

7.The flexible processing capability of the equipment is improved and the mold procurement cost is reduced

8.It is more convenient to integrate with automated equipment such as stereoscopic warehouses, automatic loading and unloading, and automatic sorting devices

| No. | Name | Parameter | Unit | Remark |

| 1 | Punching force | 300 (30) | KN (T) | 1500Nm |

| 2 | Frame structure | "O" type closed frame | ||

| 3 | Maximum plate size for one-time positioning | X-axis 3000 mm | mm | X-axis secondary positioning can process 5000mm |

| Y-axis 1250 mm | mm | |||

| 4 | Maximum plate thickness for processing | 6 | mm | |

| 5 | Maximum diameter for one-time punching | Φ88.9 | mm | |

| 6 | Maximum punching frequency | 1800 | hpm | |

| 7 | Maximum number of punching times | 800 | hpm | |

| 8 | Number of controlled axes | 5 (X, Y, Z, T, C) | Pcs | |

| 9 | Mold form | Long guide 85 series international standard mold | ||

| 10 | Turret station distribution | 16A, 11B, 3C, 2D (including rotating stations 1B, 1C) |

Standard | |

| 11 | Repositioning cylinder | 2 | Set | |

| 12 | Maximum feeding speed | X-axis 80 | m/min | |

| Y-axis 80 | m/min | |||

| 13 | Workbench structure | Brush/universal steel ball composite table | Stainless steel edging | |

| 14 | Maximum turret speed | 40 | rpm | |

| 15 | Processing accuracy | ±0.1 | mm | |

| 16 | Laser cutting range | 1250*2500 | mm | |

| 17 | Laser cutting power | 3000 | W | |

| 18 | Laser cutting accuracy | ±0.1 | mm | |

| 19 | Laser Y-axis travel | 1250 | mm | |

| 20 | Laser Z-axis travel | 150 | mm | |

| 21 | Laser cutting blanking size | ≤30 | mm | |

| 22 | Total number of equipment axes | 7 (X, Y, Z, T, C, Z, Y) | Pcs | |

| 23 | Overall dimensions | 6500*5000*2230 | mm |

In addition to normal punching, the punching machine can also realize a variety of stamping processes such as blinds pressing, convex hull, and rolling ribs. Blinds pressing is widely used in ventilation equipment and decorative products. Through precise pressure control, beautiful and practical blinds can be pressed out. The convex hull process helps to form a raised structure on thin plate materials. This structure is very common in the manufacture of electronic equipment housings and some parts that need to be strengthened. Rolling ribs can be either straight or arc ribs.

| Name | Configuration/Model | Quantity | Remark | |

| Control system | Independent research and development | 1 | ||

| Servo CNC turret punching machine host | 1250/1500/2300*5000 | 1 | 32 stations | |

| Laser cutting device | Cutting head | Shanghai Jiaqiang/BM110 | 1 | Customized |

| Laser | Chuangxin-3000W | 1 | Customized | |

| Water chiller | Wuhan Hanli/HL-3000QG2/2 | 1 | Customized | |

| Laser blanking | 1 | Standard | ||

The punching and laser cutting machine cleverly combines the advantages of punching and laser cutting. While processing according to a variety of stamping processes, it also has the function of laser cutting, which means that it can easily handle both complex and standard workpieces, greatly improving the processing efficiency of workpieces.

Punch machine configuration

The punching and laser cutting machine can achieve seamless connection between stamping and laser cutting. During the production process, the equipment can automatically switch between stamping and cutting processes according to the preset program, which greatly reduces the transfer time and processing errors of the workpiece between different equipment, thereby improving production efficiency, and also ensuring product quality and production stability. Compared with traditional processing equipment, it has greatly improved precision. Traditional equipment such as ordinary punching machines can often only perform single and rough operations, while the punching and laser cutting machine combines stamping and laser cutting technology, relying on molds and precise parameter control, and can process high-precision and complex-shaped parts, and the precision can be maintained stable. In terms of processing efficiency, traditional equipment processing relies on manual operation and has cumbersome steps, while the punching and laser cutting machine has a high degree of automation, automatic loading and unloading and fast mold changing functions, can operate continuously, and can mass-produce products such as automotive parts, effectively reducing auxiliary time. In terms of production cost, the punching and laser cutting machine has obvious cost advantages.

Laser cutting machine configuration

In terms of laser cutting, the laser fast cutting process is a highlight of the punching composite machine. Laser cutting has the characteristics of high precision, high efficiency and high stability. In sheet metal processing, it can quickly and accurately cut various complex shapes. Whether it is a straight line, a curve or various special-shaped contours, laser cutting can easily cope with it. The main configuration of the laser cutting machine is shown in Figure.

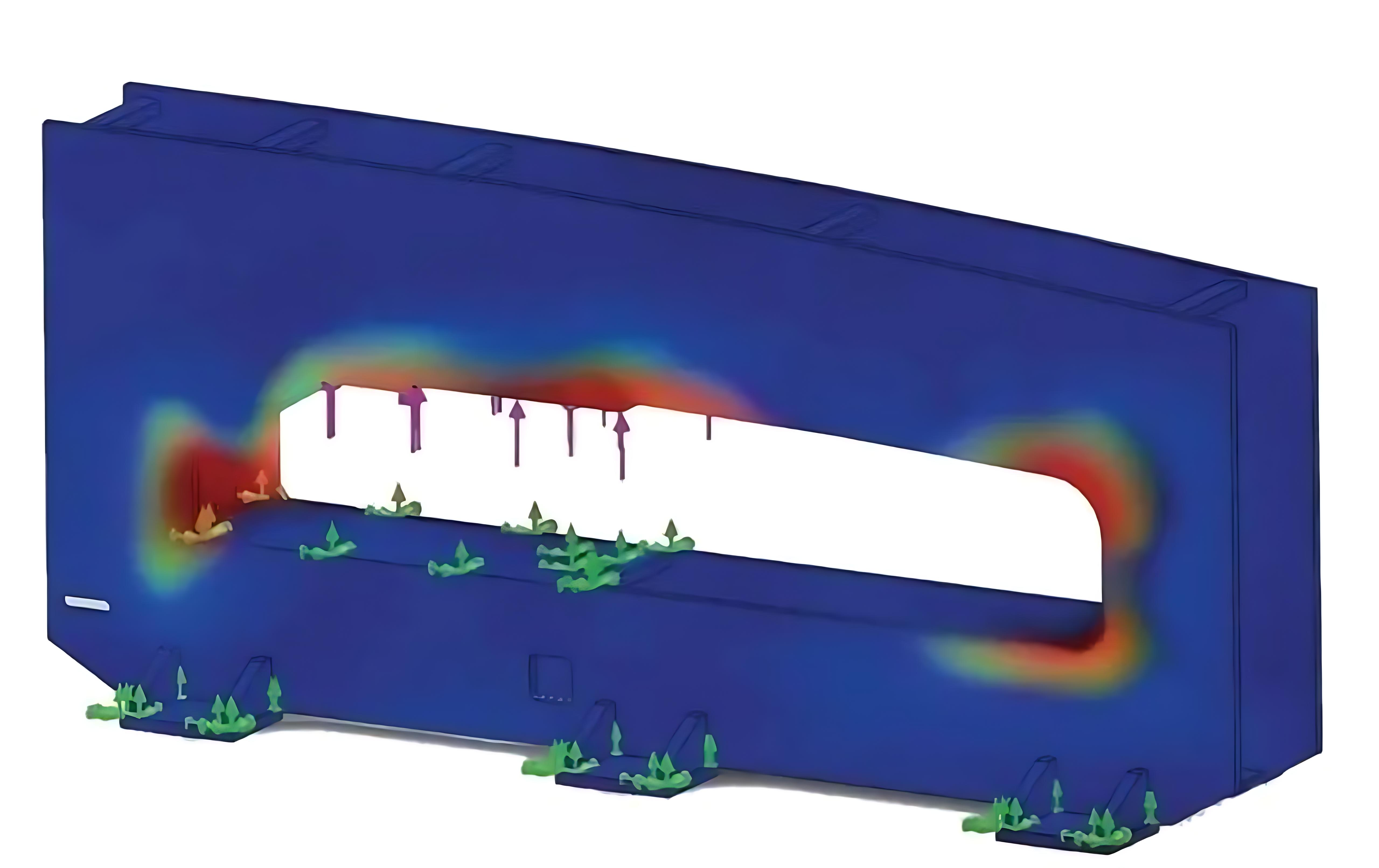

Equipment stability

The frame is welded with steel plates and is tempered and aged in the open air to eliminate internal stress, as shown in the figure. This prevents the machine body from deforming, ensures the stability and reliability of the equipment in long-term high-speed operation, and reduces production interruptions and maintenance costs caused by equipment failures.

Wide product applicability

⑴Flexible response to diverse needs. It has strong adaptability to multi-variety and small-batch production modes, and can quickly switch between different processing tasks and process parameters to meet the personalized needs of different customers. In the context of increasingly diversified and personalized market demands, it can effectively improve the market competitiveness of enterprises.

⑵Strong processing capabilities for complex shapes. It can complete the processing of various complex shapes, including complex forming processes such as cutting, countersinking, turning holes, and rolling ribs of special-shaped contours, and can meet the processing needs of complex-shaped workpieces in different industries, such as automobile manufacturing, aerospace, electronic equipment, etc.

Automation configuration

Automatic loading and unloading device can realize fully automated production from raw material loading, processing to finished product unloading, reduce manual intervention, improve production efficiency and product quality stability, reduce labor intensity and labor costs, and is particularly suitable for large-scale production needs.