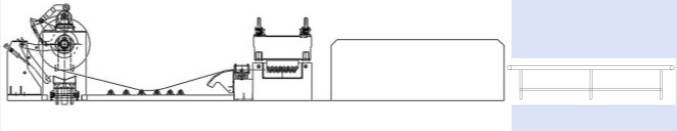

1.Including coil material rack, uncoiling and leveling device, laser machine bed, material receiving platform, automatic blade rotating assembly

2.Provide corresponding technical solutions free of charge according to the weight, width, plate material and thickness of the steel coil

3.Cutting efficiency is higher, reducing the time of loading the plate, and only need to pick up the waste, which is 50% more efficient

4.Reduce labor intensity. No need to cut materials to size or lift boards manually

5.Improve the efficiency of sheet material use, realize cutting as much as needed, and avoid the disadvantage of needing to make compensation after each sheet is cut

6.It can realize one system control, automatic sorting and processing, and manual and automatic integration. The operation is simple and easy to use, which is more user-friendly than ordinary machines that need to import graphics every time.

Equipment parameters

|

|

Raw materials |

Cold rolled sheet, galvanized sheet, stainless steel |

|

2 |

Plate thickness |

0.5mm ~ 2.0mm |

|

3 |

Plate width |

1000mm~1500mm |

|

4 |

Weight per roll |

≤10T |

|

5 |

Inside diameter of roll |

Ø508mm-Ø630mm |

|

6 |

Outer diameter of roll |

Ø1000 ~ Ø1600mm |

Finished product parameters

|

1 |

Surface quality |

The surface of the strip is flat and does not add any processing defects; |

|

2 |

Leveling accuracy |

±1mm / m2 |

|

3 |

Diagonal accuracy |

≤1mm/2000mm |

Unit Parameters

|

1 |

Belt speed |

5m/min |

|

2 |

Line speed of the unit |

Straightening machine line speed 0~12m/min (adjustable) |

|

3 |

Running Elevation |

+800mm |

|

6 |

Running direction |

(Subject to final plant process layout) |

Working conditions for equipment use

|

1 |

Power conditions |

3φ alternating current, 400V±5%,50Hz±2% |

|

2 |

Air source (compressed air) |

Pressure: 0.5~0.6MPa Displacement: 0.6m3/min |

|

3 |

water source |

No special requirements |

Equipment Painting

|

1 |

Mainframe Paint Color |

Standard |

|

2 |

Mobile, security and other components |

Configuration according to primary color (yellow/orange) |

|

3 |

Electrical cabinets, operating consoles, fuel tanks |

Standard |

Equipment Main Configuration

|

No. |

Category |

Name |

Origin and Brand |

Quantity |

|

1 |

Laser |

Fiber laser |

Shenzhen Chuangxin 6000W |

1 |

|

2 |

laser head |

Fiber laser cutting head |

Shanghai Jiaqiang |

1 |

|

3 |

Cooling system |

Water cooler |

Wuhan Hanli |

1 |

|

4

|

CNC system

|

Motion control system |

Shanghai Weihong |

1 |

|

Servo Motion System |

Shenzhen Weichuang |

4 |

||

|

Reduction gear |

Japan Beto |

3 |

||

|

Electrical Components |

Schneider, France |

1 |

||

|

Pneumatic Components |

Anwuochi, Germany/Yadek, Taiwan |

1 |

||

|

5

|

Machine body

|

Operating table |

Cantilever type |

1 |

|

Guide rail |

Taiwan Heqing |

1 |

||

|

Slider |

Taiwan Heqing |

10 |

||

|

Rack and pinion |

Taiwan Kotai |

1 |

||

|

Bed |

Welding and aging treatment of square tube |

1 |

||

|

Smoke exhaust |

Smoke duct |

1 |

||

|

6

|

Auxiliary facilities

|

Material rack |

10T hydraulic material rack |

1 |

|

Leveling machine |

15-roller precision leveling machine |

1 |

||

|

Splicing machine |

Roller splicing table / belt plate splicing platform |

1 |

||

|

Air compressor |

1.6Mpa air compressor specialized for laser |

1 |

Working environment requirements

|

Item |

Name |

Requirements |

Remarks |

|

Power supply

|

Total installed capacity Voltage |

≤50KVA 380V/220V±5% |

Recommended to use 100kva capacity power supply Other areas must be installed with automatic voltage and current stabilizers. |

|

Grounding resistance |

≤4 ohm |

||

|

There should be no strong electromagnetic signal interference near the installation equipment. Avoid radio transmitting stations or relay stations around the installation site. |

|||

|

Water |

Water cooler water |

Must use purified, deionized or distilled waterGases |

|

|

Gas |

Oxygen, Nitrogen |

Purity > 99.5% |

Parameters vary according to material processing |

|

Air compressor |

Pressure ≥1.6mpa |

||

|

Work Environment

|

Temperature |

5-40 degrees |

|

|

Humidity |

≤80%, no condensation |

||

|

Foundation |

Amplitude <50um, amplitude acceleration <0.05g; no large stamping vibration equipment nearby. |

If the source of vibration need to do anti-vibration trench |

|

|

Equipment space requirements to ensure that no smoke and dust, to avoid metal polishing and grinding and other dusty working environment, and must be installed anti-static flooring, connecting shielded wire |

|||

Hydraulic cantilever uncoiler

|

Type: cantilever type, with side hydraulic auxiliary support, hydraulic expansion and contraction. Function: The unwinder is used to open the coil and establish synchronous residual material with the leveling machine. Structure: Roller type, with guide column screw structure, hand wheel adjustment. Body and base: welded structure, heat aging treatment. Material of main shaft: 40Cr, quenched and tempered

|

Four-stage leveling machine

|

Equipment used to level uneven steel plates. The leveling machine adopts a single-layer roller structure. Each leveling roller is fine-turned, tempered, chrome-plated, and ground to ensure surface hardness and finish, and to achieve the best leveling effect. The single machine can move forward and reverse. After leveling, it is directly connected to the coating mechanism to complete the coating of the steel plate to protect the plate surface from scratches. |

|

Used to measure the length of the steel strip and feed back the data to control the laser to cut the plate. The unit adopts a fixed length system. The human-machine interface directly inputs the required plate length and has a digital display. The quantitative quantity of the plate is automatically controlled by the counter. |

Laser cutting machine

|

The overall welded structure is rough-machined after annealing to eliminate internal stress, and fine-machined after secondary vibration aging treatment. There is a smoke extraction port under the bed, and smoke is extracted through the smoke exhaust pipe, which can easily discharge the smoke and dust generated during the cutting process to the outdoors. Gantry structure. High-precision rack and pinion double-sided drive. High-torque French imported flange output reducer. |

Other components

|

|

|

Hydraulic and pneumatic systemHydraulic station and hydraulic pipeline.Pneumatic system. An integrated pump station is used to provide hydraulic power to each cylinder, and is equipped with corresponding overflow valves, pressure gauges, pressure regulating valves, check valves, solenoid valves, etc.

|

Water cooling systemCan realize dual temperature and dual control. Two water circuits cool two core positions respectively. The temperature of the refrigeration unit is displayed on a digital meter. When the water temperature exceeds the specified temperature, the refrigeration unit will automatically cool. When the water temperature is lower than the specified temperature, the refrigeration unit will automatically stop cooling.

|

CNC control systemEquipped with AutoCAD, CorelDraw and other professional drawing software.Specially developed for CNC cutting machines, it is a drawing, programming and nesting software used on computers. The main functions include CAD drawing, the new version of CAM-DUCT duct decomposition software, DXF/DWG optimization processing, interactive nesting, automatic programming, cutting simulation verification and cost calculation.

|

Size

The 3015 model has an effective cutting stroke of 3 meters long * 1.5 meters wide, the total length of the machine occupies about 20 meters, and the width occupies about 5 meters.

Service Commitment

Pre-sale service:

According to the development needs of customers, from the point of view of the actual use of customers, to provide appropriate technical guidance and a full set of equipment information;

Solve the various problems raised by customers, from the technical feasibility considerations, for customers or to assist customers in the design and development of laser processing program;

Provide equipment display so that customers can visit the inspection, sampling, test machine and so on.

In-sale service:

The actual use of the customer's machine site inspection and analysis, according to the customer's site to assist users in planning and design of the site as well as water, electricity, gas arrangements for the equipment and so on;

Provide customers with a full set of equipment operation manuals, equipment operators to provide training to customers;

After-sales service:

In the user's use of the site, the customer's equipment operators for the actual operation of the processing, daily maintenance of equipment and safe use of the protection of the training to ensure that the user can master the equipment operating procedures and methods as soon as possible, and can independently use the equipment for production and processing;

The whole set of equipment in the user after installation and commissioning, since the date of training into the machine one year warranty period, the laser two years warranty period;

In the warranty period, the company will also assign customer service specialists to the user's equipment from time to time to carry out technical patrols on the work site, the equipment to do from time to time routine maintenance and inspection, to answer questions raised by the user.

Other matters

1、Project progress

Cycle time of about 45-60 working days, according to the contract cycle time to complete the design, manufacturing and acceptance of work and sent to the demand side.

2、Installation and commissioning

Equipment shipped to the demand side, 7-10 days of installation and commissioning cycle.