1.Model:STSK-SF25/STSK-SF30/STSK-SF40

2.Provides 25/30/40 tons of punching force,1250/1500/2000/2300mm optional

3.Max punch thickness:CS 3mm,MS 4mm, SS 3mm, GI 4mm,AL 6mm

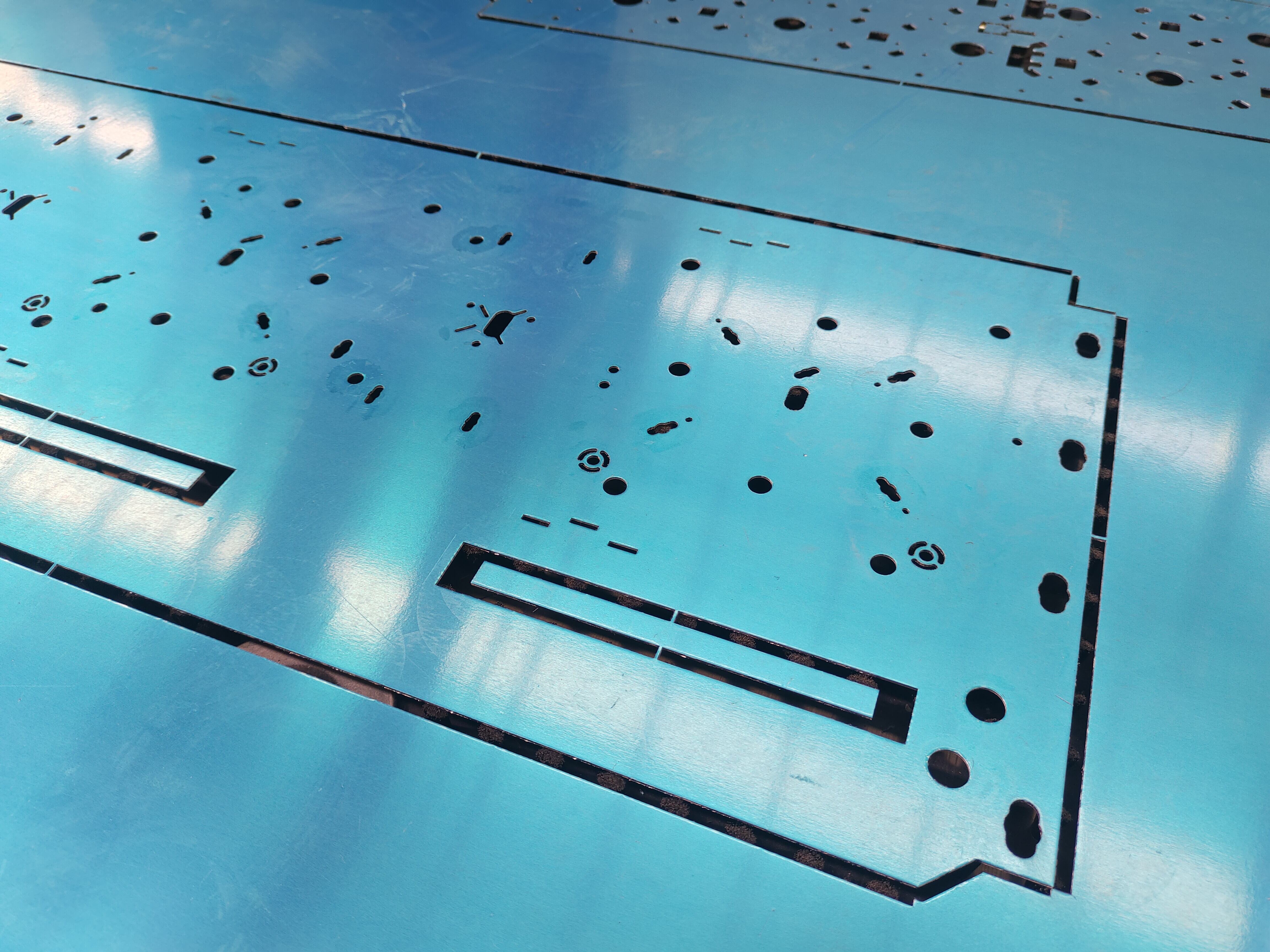

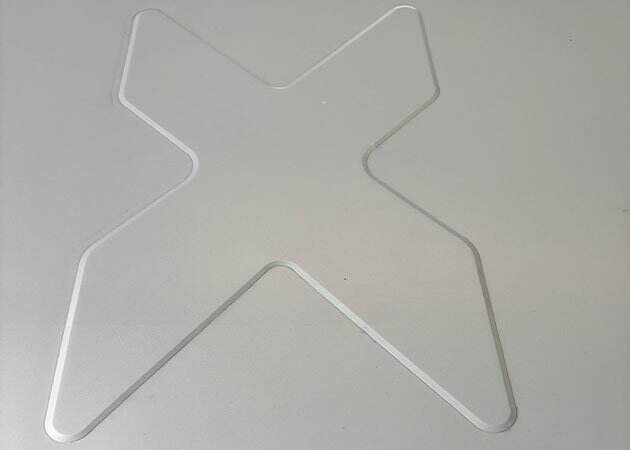

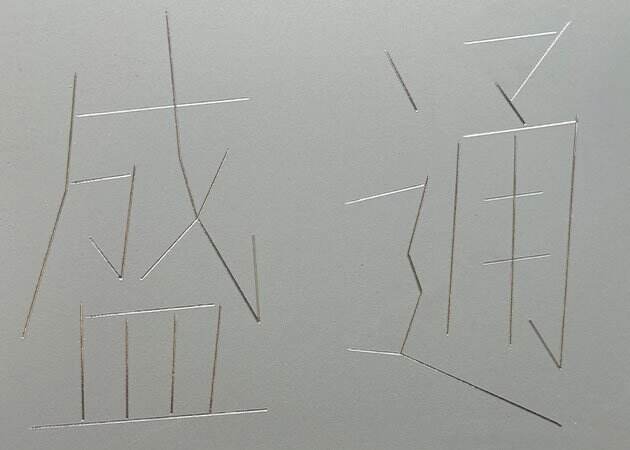

4.Capable of performing punching, drawing, beading, marking,shutter and complex shape

5.Installation:Engineers on-site /remote online guidance/customers on-site learning

6.Pre-sales engineers review drawings and make free samples

7.Sheet metal processing: used for batch punching and forming of sheet metal parts such as power distribution cabinets, elevator panels, chassis cabinets, etc.

8.FANUC system optional

|

No. |

Name |

Parameters |

Unit |

Remarks |

|

1 |

Punching force |

250(25)/300(30)/400(40) |

KN(T) |

|

|

2 |

Frame structure |

O” type closed frame |

|

|

|

3

|

Primary positioning Max. machined plate size

|

X-axis 2,500 |

mm |

(X-axis secondary positioning machinable 5,000mm) Customizable |

|

Y-axis 1,250/1,500/2,000/2300 |

mm |

|

||

|

4 |

Max. machined plate thickness |

6 |

mm |

Aluminum plate |

|

5 |

Max. diameter of one punch |

Φ88.9 |

mm |

Customizable |

|

6 |

Max.punching frequency |

1,800 |

hpm |

|

|

7 |

Max.number of punches |

800 |

hpm |

|

|

8 |

Number of controlled axes |

5 (X, Y, T, C, R) |

Pcs |

|

|

9 |

Mold type |

Long guide 85 series international standard mold |

|

|

|

10 |

Turret station distribution |

16A, 11B, 3C, 2D (Including rotary stations 1B and 1C) |

Standard |

Customizable |

|

11 |

Repositioning cylinder |

2 |

Set |

|

|

12 |

Number of clamps |

3 |

Pcs |

|

|

13

|

Max.feeding speed

|

X-axis 80 |

m/min |

|

|

Y-axis 80 |

m/min |

|

||

|

14 |

Workbench structure |

Brush/universal steel ball bench top |

|

Stainless steel wrap |

|

15 |

Max. turret speed |

40 |

rpm |

|

|

16 |

Processing accuracy |

±0.1 |

mm |

|

|

17 |

Max. load bearing |

150 |

Kg |

|

|

18 |

Total power |

5 |

KW |

|

|

19 |

Airsource pressure |

0.55 |

MPa |

|

|

20 |

Power supply |

380±5% |

V |

|

|

21 |

Dimensions |

L×W×H 5,000/5,500/6,500×7800×5200×2,100 |

mm |

Punching machine detail introduction collation

| Working Stations |  |

The turbine worm reducer and double-chain drive are used to drive the cutter head. The reducer is installed inside the frame to enhance the transmission stability and displacement accuracy. The cutter head is designed with an enlarged cylinder seat and two cylinders, which has can run synchronously and position stably and accurately to avoid the wear of the side sleeve of the cutter head. |

| Rotary Station |  |

The rotary station (rotation by itself) is driven by a synchronous belt, which has the advantages of fast transmission speed, high precision and low noise. |

| Cutter Head |  |

The cutter head is made of 45# carbon steel, is quenched and tempered,and processed by a large CNC surface grinder after turning and milling to ensure the flatness and smoothness. The special fixture is used to process the positioning holes in pairs to ensure the coaxiality of the upper and lower dies.The company is equipped with a large imported (Hexagon, Sweden) three-coordinate measuring instrument and the cutter head is assembled after passing the test. |

| Servo Motor |  |

High-power hollow shaft servo motor is used to output power and the crankshaft is connected to the servo motor as a whole to avoid the misalignment and delay caused by too many connections. The direct-drive punching operation is featured by high stability and fast response speed, and the swing method is adopted. The swing angle is automatically selected according to the punching stroke and process to greatly improve the efficiency. |

| X Axis |  |

The X-axis square tube beam is designed with two guide rails. After tempering treatment, the self-weight of the components is reduced, the operation is more stable and the positioning is more accurate. The guide rails and lead screws are imported from Taiwan and they are assembled according to strict and scientific assembly process. The company is also equipped with advanced laser collimator and laser interferometer to ensure assembly accuracy and effectively improve feeding accuracy and operating speed. |

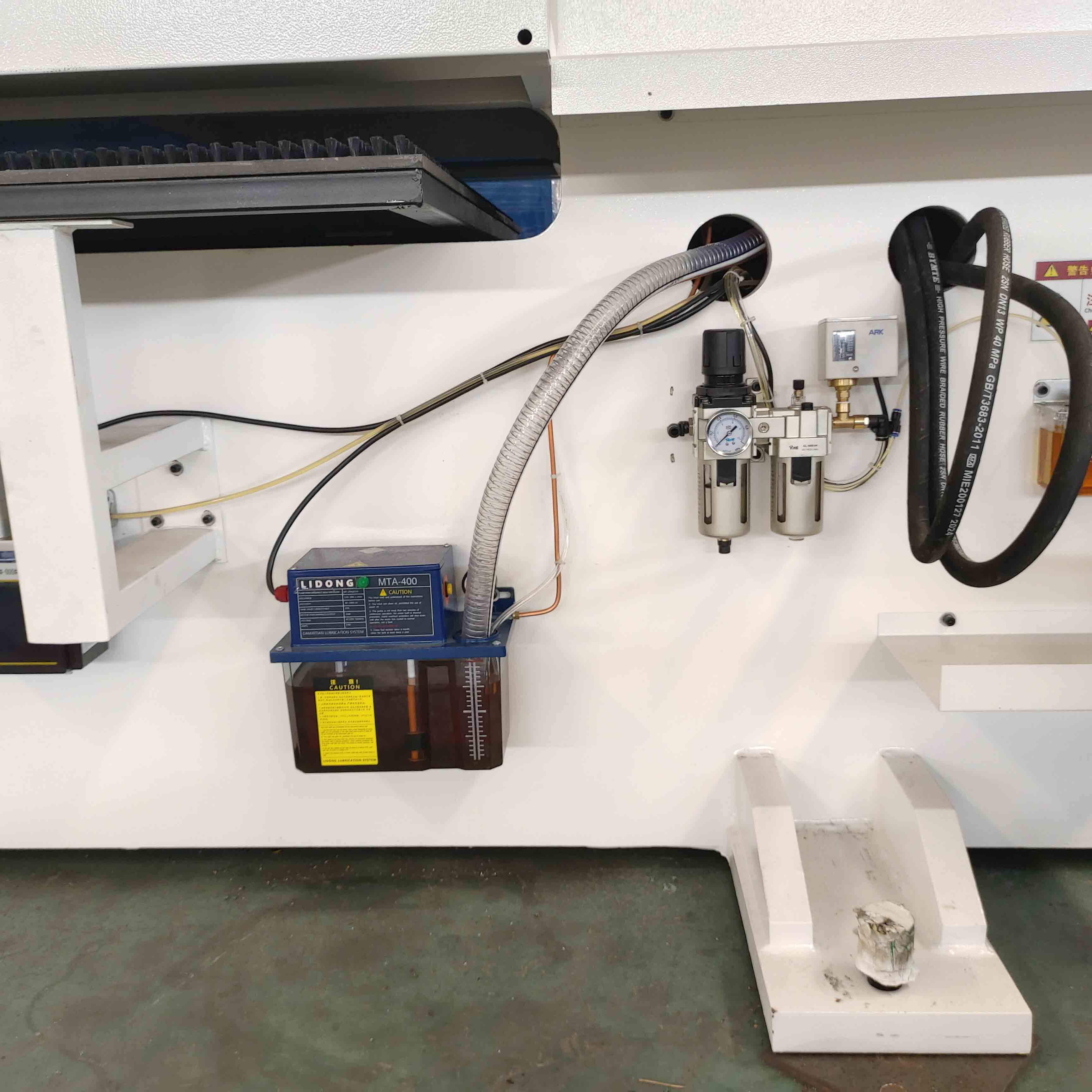

| Oil Cooler |  |

Servo motor is oil-cooled by using the oil cooler, which has the advantages of low temperature rise and high overload capacity. It solves the problem of frequent replacement of coolant in cold areas in winter. |

| Floating pneumatic clamp |  |

Floating pneumatic clamp is used with large clamping force and stable feeding capacity. The integrated dovetail carriage has good rigidity and the clamp is easy to move. The clamp can automatically float down during feeding, making it easier for the plate to enter the clamp to greatly reduce the labor intensity of the operator. |

| Secondary Positioning |  |

Equipped with secondary positioning function, which adds double insurance to accuracy. Through advanced sensor and accurate control system, realize real-time monitor the workpieces in processing and re-positioning, ensure each motion is accurate. This avoid the processiing error caused by various factors after the first positioning. |

| Anti-collision Mechanism |  |

When the system determines that there is a collision risk, it will immediately trigger the anti-collision mechanism. This includes urgently stopping all moving parts of the machine. This mechanism protects both the workpieces and the machine parts from being collided. |

| CONTROL SYSTEM |  |

The host computer is equipped with imported motherboard and motion control card, coupled with Panasonic RTEX bus servo unit, for full closed-loop signal transmission. The bus control mode has fast communication speed and short cycle, which greatly improves the accuracy of cooperation between axes when multiple -axes work together. |

| ELECTRIC COMPONENTS |  |

Adopt famous imported electrical equipment to ensure the stability of the control system. |

| LUBRACATION SYSTEM |  |

The multi-point automatic lubrication system is adopted to ensure complete lubrication of each moving part and avoid wear due to inadequate lubrication. |

Shutter Forming |

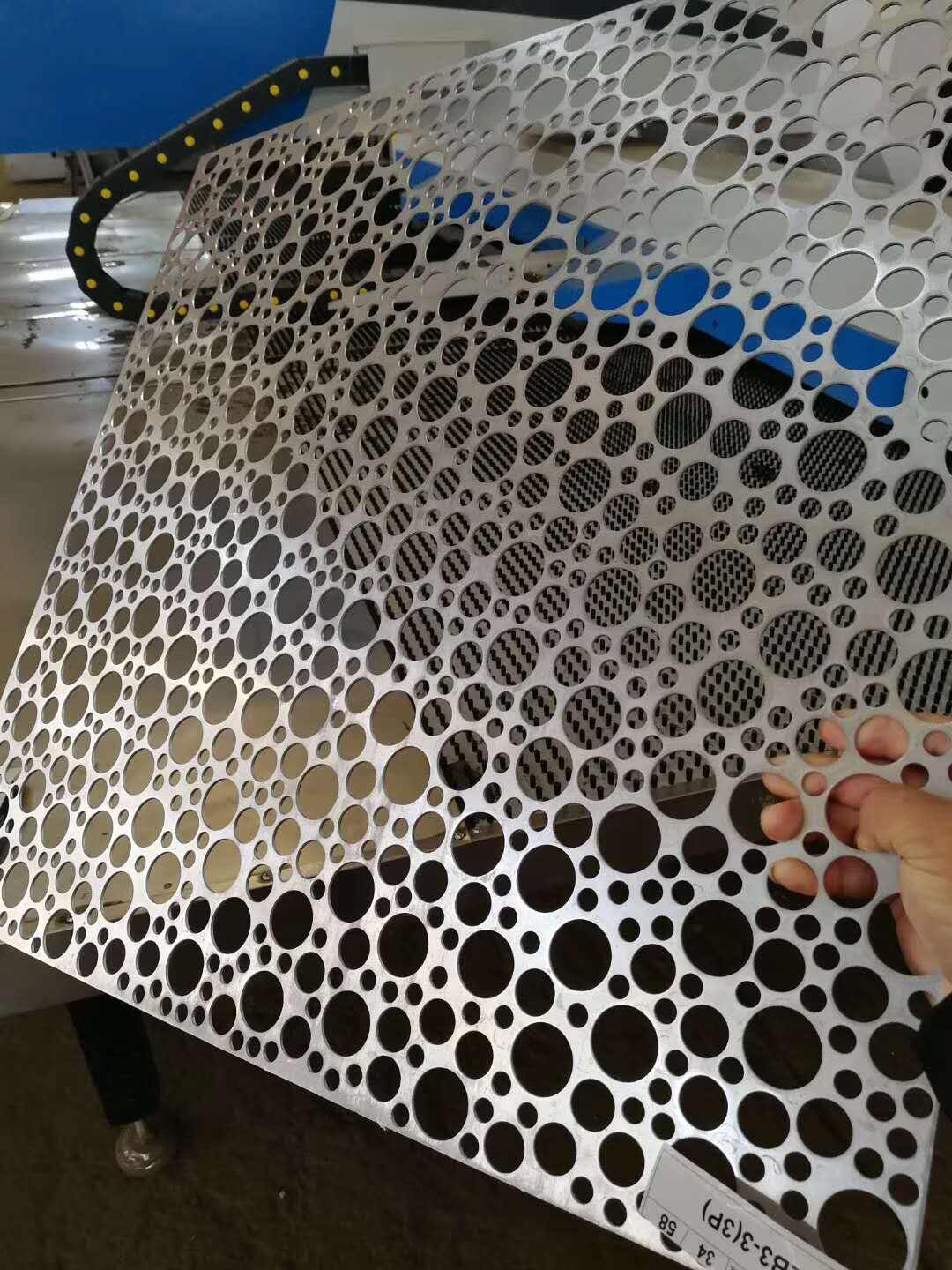

Patterned Curtain Wall |

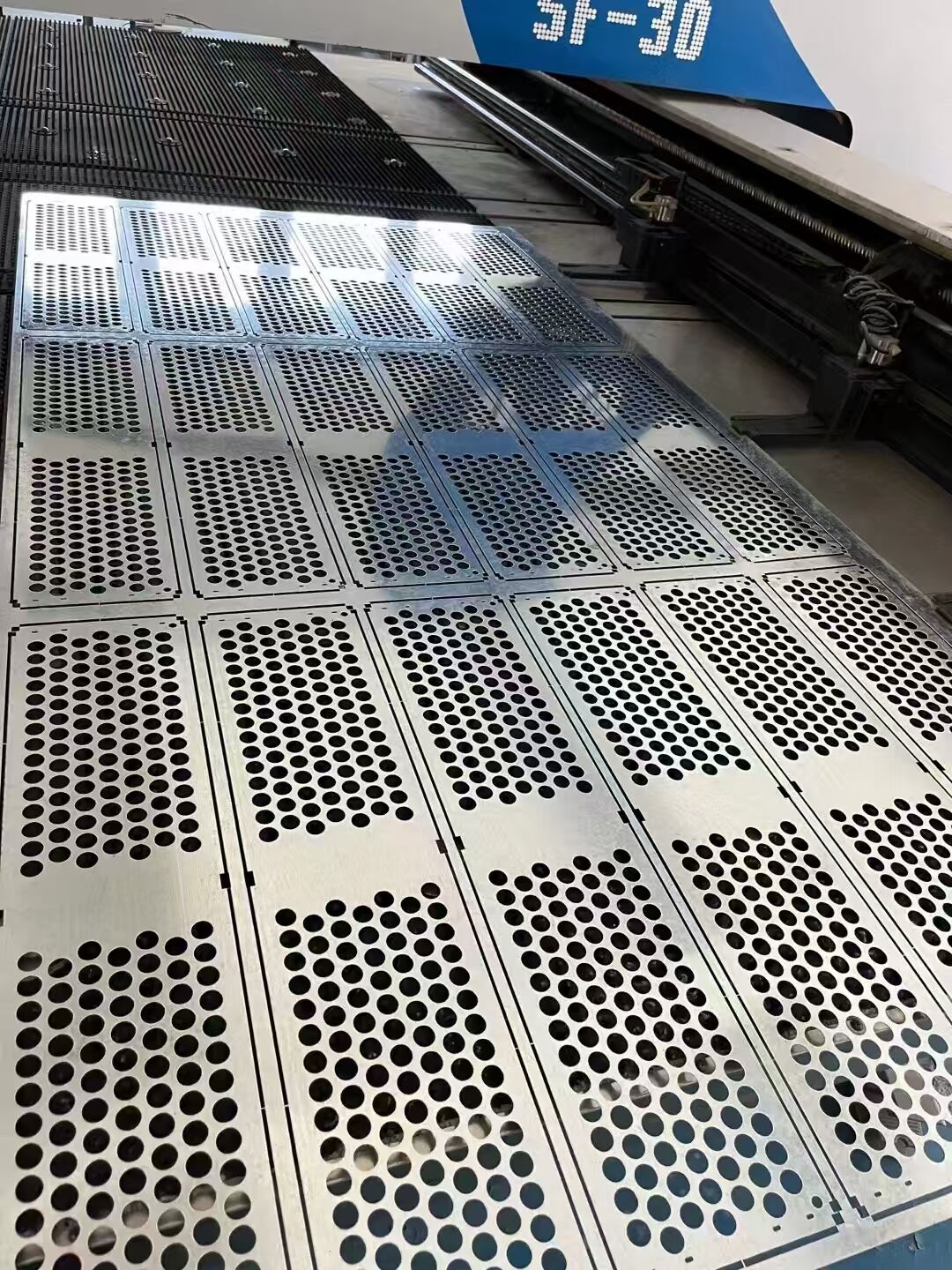

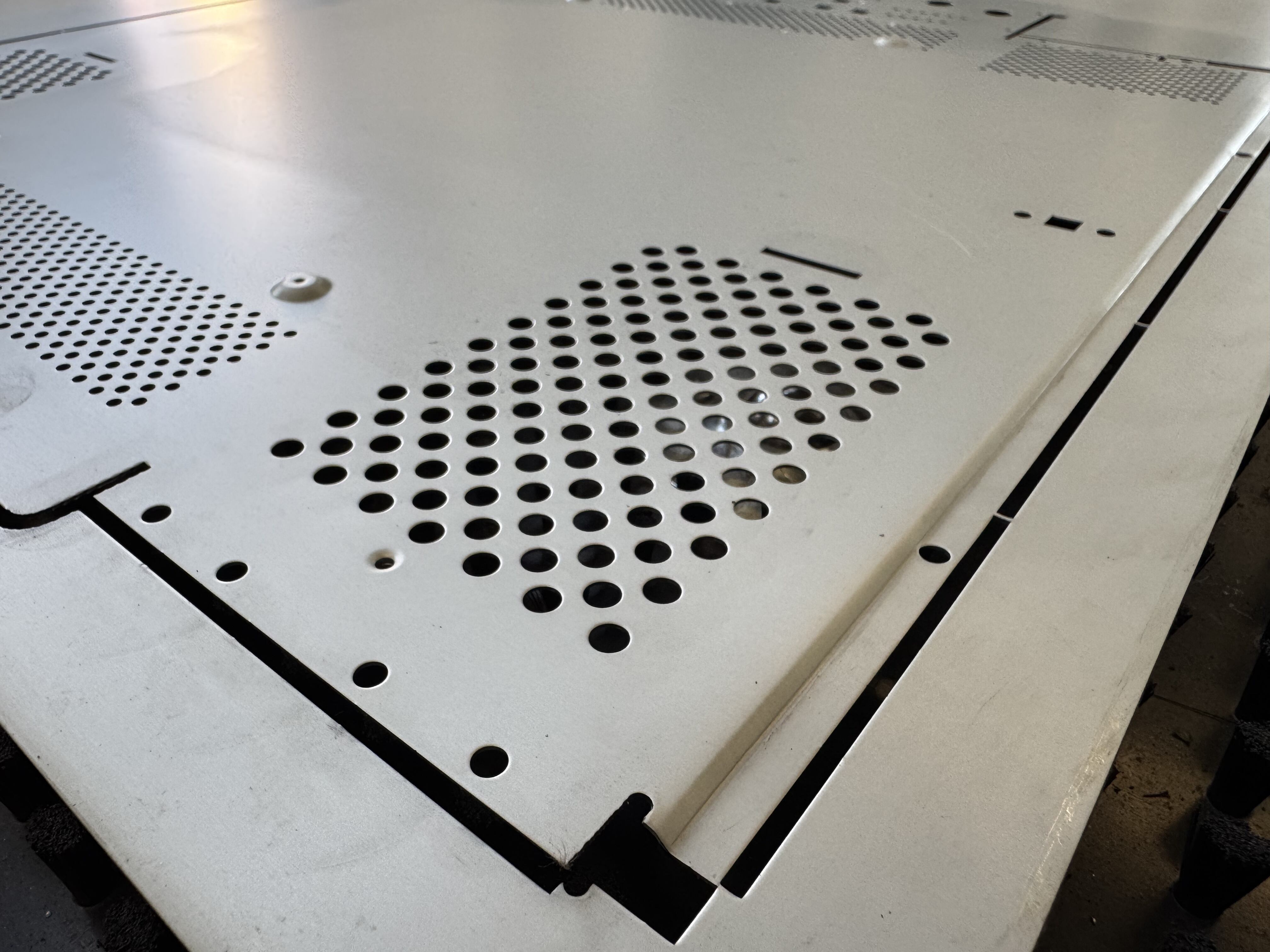

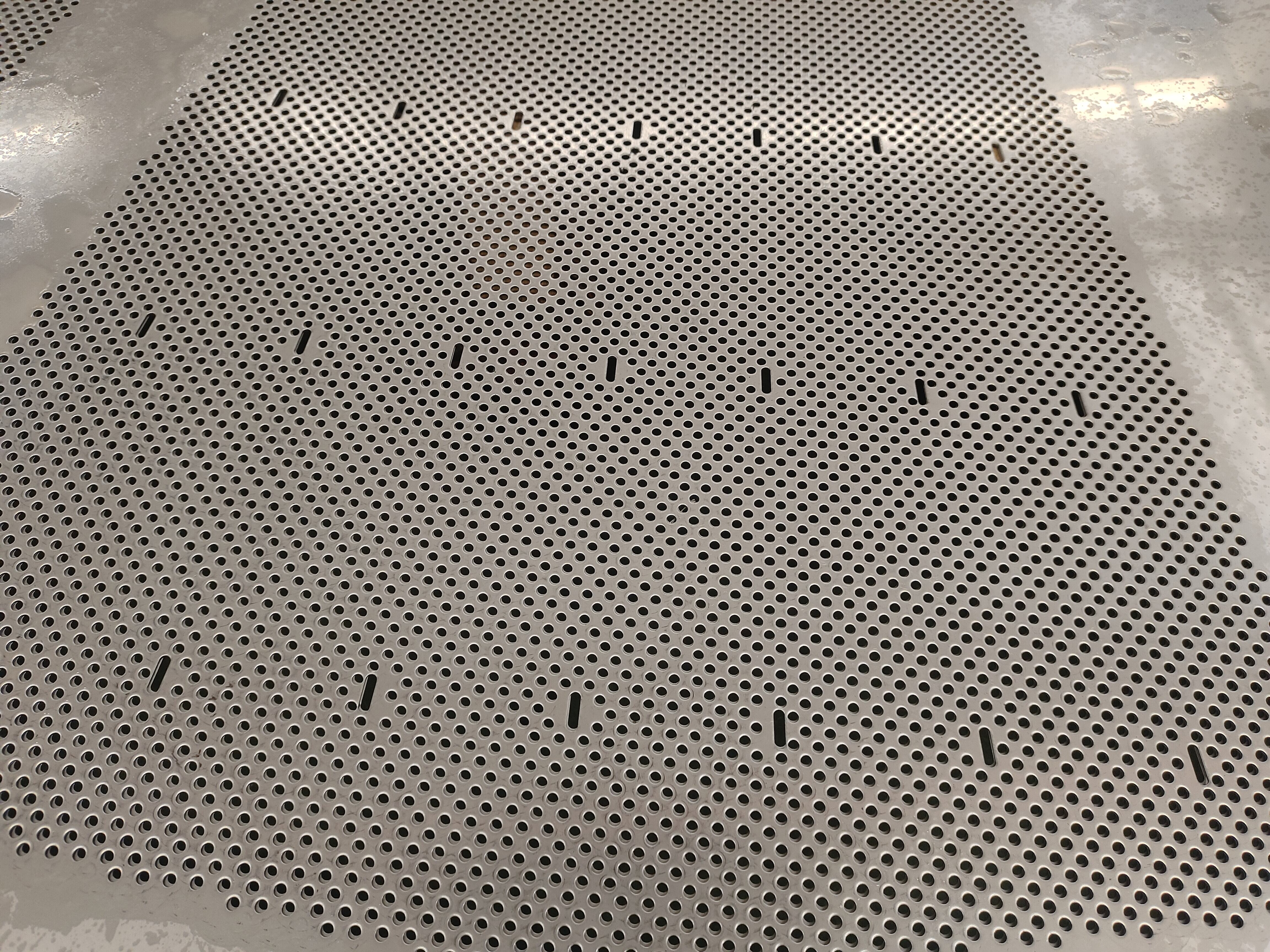

Hole Punching |

Burring |

Decorative curtain wall |

Machine housing |

Filter Screen |

Lamination punching |

Rolling |

Marking |

Emboss |

Nibbling |

|

No. |

Name |

Specifications |

Supplier/Brand |

|

1 |

Servo punch motor |

45KW(1200Nm)/55KW(1500Nm) |

Synmot, Ningbo |

|

2 |

Drive controller |

75KW/90KW |

Synmot, Ningbo |

|

3 |

Cooling tank |

Volume 96L, cooling capacity 1,200ml/min |

Synmot, Ningbo |

|

4 |

Encoder |

Multiple rotary, 1024 lines |

Tamagawa, Japan |

|

5 |

Encoder cable |

RVVP shielded twisted pair |

Imported from Taiwan |

|

6 |

Magnetic steel |

Grade AH |

Ningbo Yunsheng |

|

7 |

Temperature sensor |

MZ6-150-DS |

Santest, Japan |

|

8 |

Filter |

DL-180EBT |

Synmot, Ningbo |

|

9 |

DSP |

TI 28324 |

Rockwell, USA |

|

10 |

Mold |

400A |

Fuji, Japan |

|

11 |

CPLD |

|

Alter, USA |

|

12 |

PCB |

SYNMOT-90KW |

Taiwan Delta |

|

13 |

HALL |

|

Honewell, Germany |

|

14 |

Driver fan |

|

Taiwan Delta |

|

15 |

Hall sensor |

TBC400BS |

HBM, Germany |

|

16 |

Input isolation reactor |

90KVA |

Ningbo Mingchuan |

1.Are you a trading company or manufactuer ?

We are factory, so we have competitive price and we have our own foreign trade team so we also have attentive service.

2.What is the average lead time ?

For samples, the lead time is about 7 days. For mass production, the lead time is 45-60days after receiving the deposit payment.

3.Are you an ODM OR OEM factory?

YES, we are ODM, you can send us your requirements then we can design for you.

4.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance against the copy of B/L.

5.Do you provide overseas after-sales service and installation and commissioning services?

Yes, we can. After the equipment arrives at the customer’s site, the company will send its full-time personnel to conduct installation and commissioning, and provide training for the operators until they can operate the equipment by themselves.

6.what can you buy from us?

CNC Turret Punch Press, CNC bending machine, Fiber Laser Cutting Machine, Bending Automation, Flexible Manufacturing System, Panel Bender and sheet plate automatic production lines.

7.what services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency:USD, EUR;RMB

Accepted Payment Type: T/T, L/C;