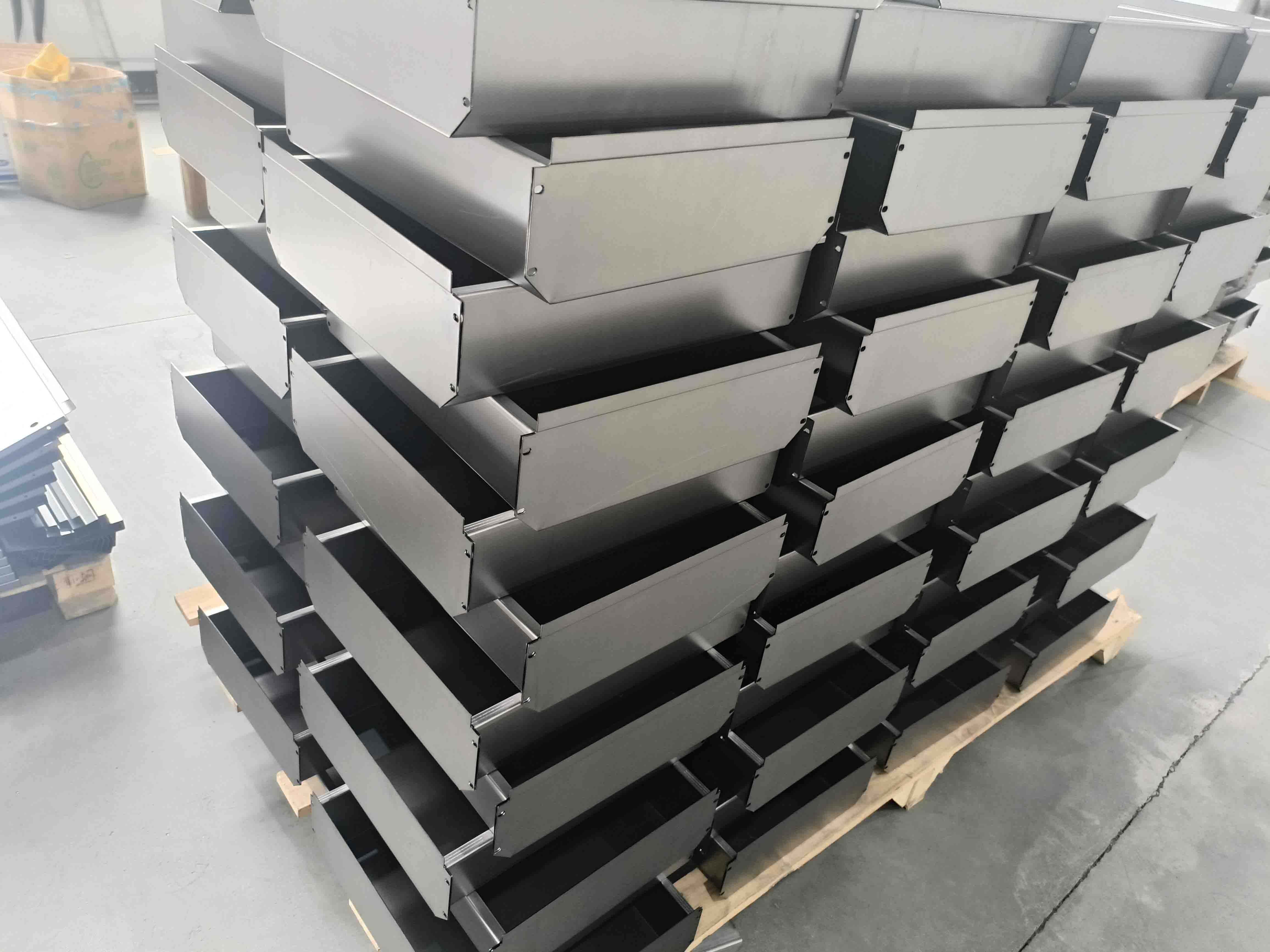

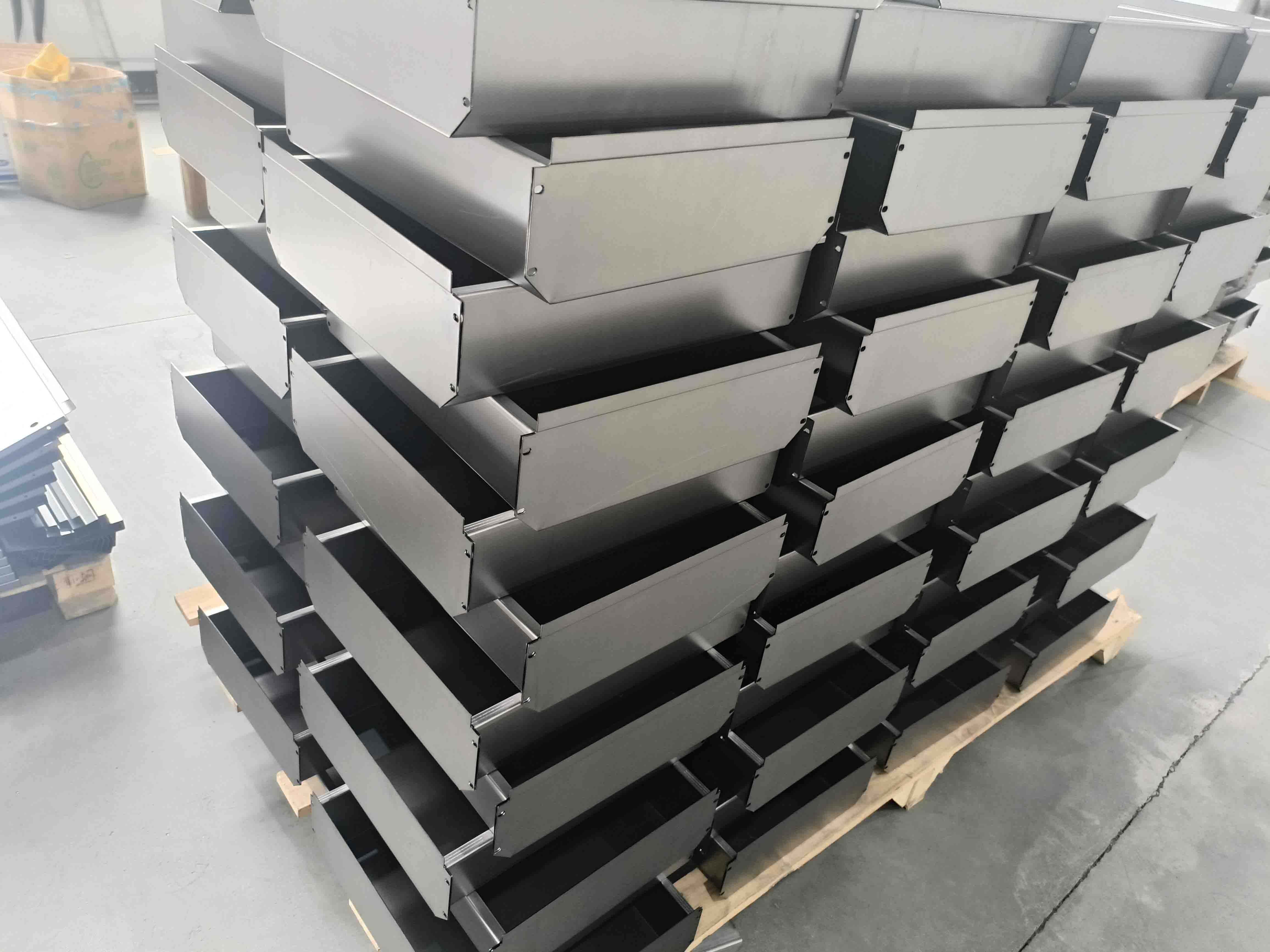

In the sheet metal industry, the CNC bending process plays a crucial role in the manufacturing of stainless drawers. Various shape of drawers can be perfectly formed by our sheet metal bending center. 1.Structural Stability: The side panels o...

In the sheet metal industry, the CNC bending process plays a crucial role in the manufacturing of stainless drawers. Various shape of drawers can be perfectly formed by our sheet metal bending center.

1.Structural Stability:

The side panels of the drawer are bent to create vertical or non-vertical supports, enhancing the overall stability of the structure. This ensures that the drawer can withstand the weight of the items placed inside without sagging or deforming.

Example: In a heavy-duty drawer, the side panels are thick sheet metal bent at right angles to provide strong lateral support.

2.Strength Enhancement:

The bottom panel is often bent at the edges to increase its strength and prevent it from buckling under pressure.

For instance: A drawer designed for industrial use may have a bottom panel with multiple bends to handle heavy loads.

3.Aesthetic Appeal:

Bending can be used to create decorative elements or unique shapes on the front baffle, adding to the visual appeal of the drawer.

Example: A designer drawer might have a front baffle with curved bends to give it a modern and stylish look.

4.Customization:

Sheet metal bending enables the production of drawers in various sizes and shapes to meet specific requirements and fit different spaces.

For instance: A custom-sized drawer for a narrow cabinet can be fabricated by precise bending of the sheet metal.

5.Production Efficiency:

Bending allows for efficient use of the sheet metal material, minimizing waste and reducing production costs.

Example: By carefully planning the bends, the manufacturer can maximize the utilization of the sheet metal sheet, reducing scraps.

6.Durability:

The bends add rigidity to the drawer, making it more durable and long-lasting, especially in demanding environments.

For example: In a workshop or garage, a sheet metal drawer with proper bends can withstand frequent use and rough handling.

In some high-end drawer designs, the bending process might also be utilized to create unique storage compartments or achieve functions such as buffered closing of the drawers through special bending shapes.