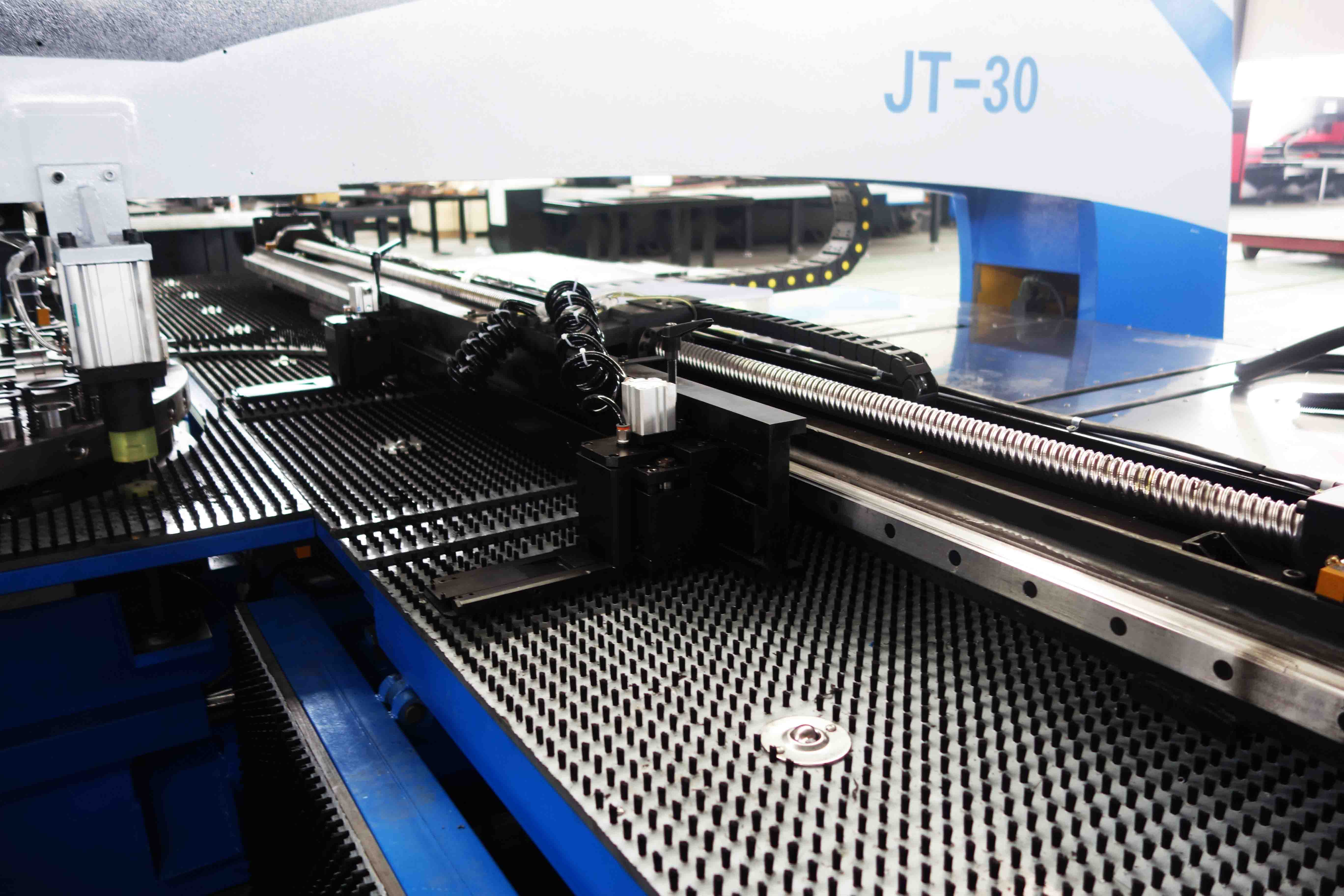

Model:STSK-JT30/STSK-JT50

Provides 30/50 tons of punching force,1250/1500mm optional

Max punch thickness:CS 3mm,MS 4mm, SS 3mm, GI 4mm,AL 6mm

FANUC system optional

Pre-sales engineers review drawings and make free samples

Installation:Engineers on-site/remote online guidance/customers on-site learning

After-sales service:24/7 respond,arrive at the user's site in the shortest possible time

Ultra-low Energy Consumption: As low as 3 kWh per hour, significantly reducing production costs

Automatic switching of multiple mold turrets reduces mold change time and is suitable for mass production

| Parameter | Unit | Remark | |

| Model | STSK-JT30/STSK-JT50 | ||

| Punching force | 300(30)/500(50) | KN(T) | |

| Frame Structure | O-Type Closed Frame | ||

| Max Sheet Size for Single Positioning |

X-Axis 2500 Y-Axis 1250/1500 |

mm | Customizable to Non-Standard |

| Max Sheet Thickness | 6 | mm | Based on Sheet Type |

| Max Punching Diameter in a Single Stroke | φ88.9 | mm | Customizable to Non-Standard |

| Max Punching Frequency | 280 | hpm | |

| Max Punching Hits | 280 | hpm | |

| Number of Control Axes | 4(X、Y、T、C) | piece | |

| Die Type | Long Guide 85 Series International Standard Die | ||

| Turret Stations Distribution | 16A、11B、3C、2D(Including Rotary Stations1B、1C) | Standard | Customizable to Non-Standard |

| Repositioning Cylinder | 2 | set | |

| Number of Clamps | 2 | Piece | |

| Max Feeding Speed | X-Axis 90 Y-Axis 80 | m/min | |

| Worktable Structure | Brush and Universal Ball Composite Work Surface | ||

| Max Turret Speed | 40 | rpm | |

| Processing Precision | ±0.1 | mm | |

| Max Load Capacity | 150 | Kg | |

| Total Power Consumption | 3 | Kw | |

| Air Source Pressure | 0.55 | Mpa | |

| Power Supply | 380±5% | V | |

| Overall Dimension | 5000/5500×5200×2100 | mm |

Curtain Wall |

Shutter |

Stretch |

Bridge |

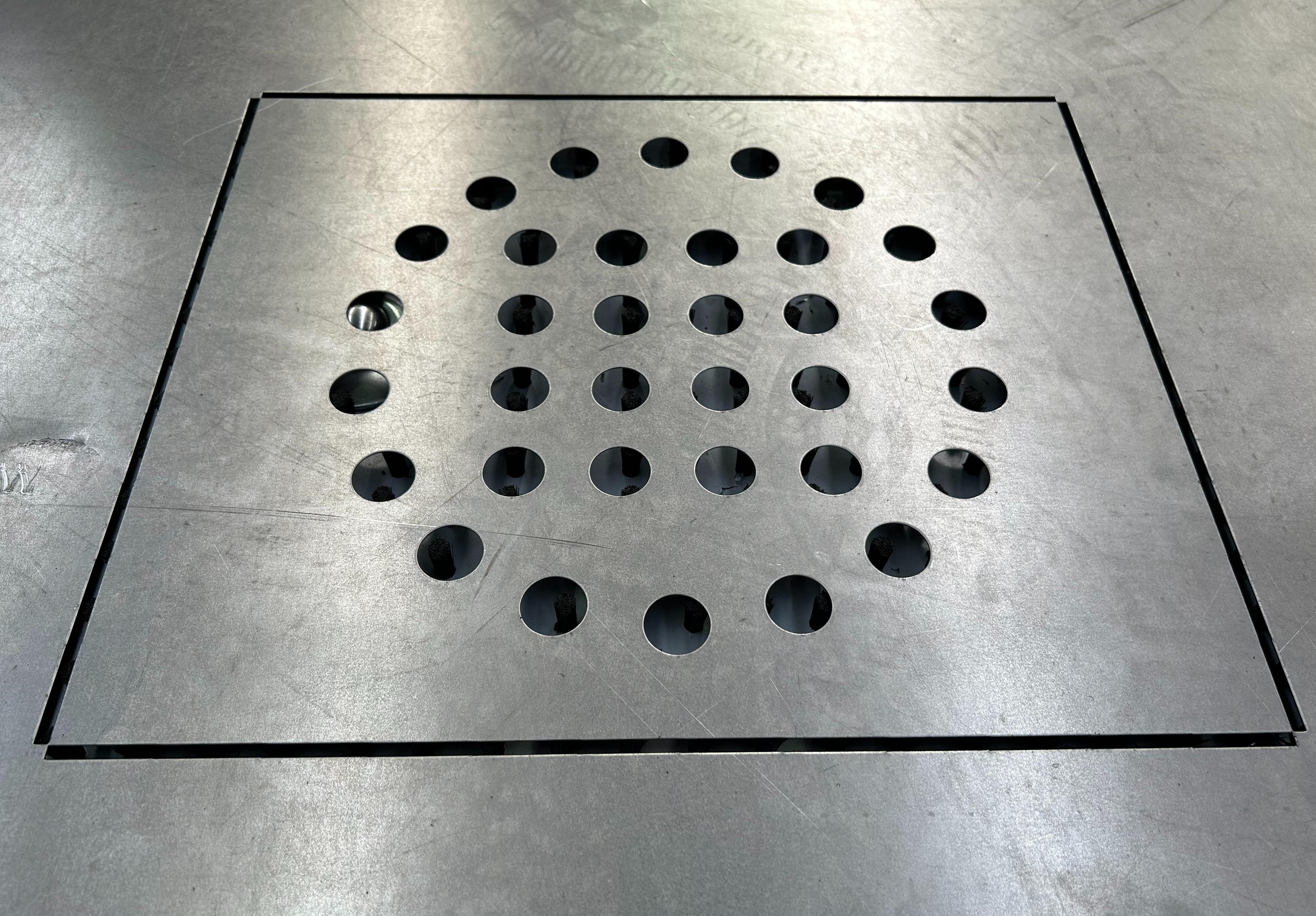

Hole Punching |

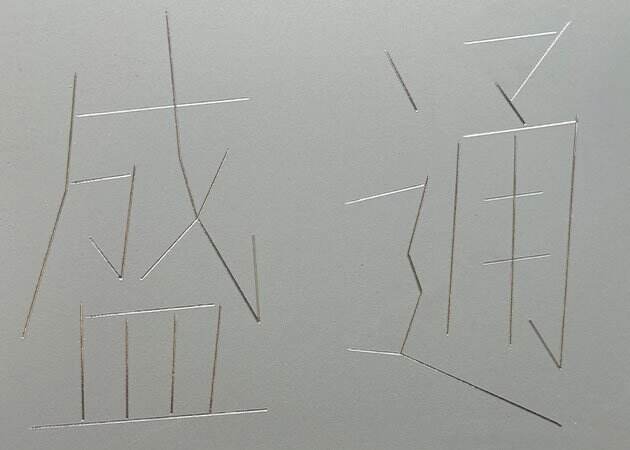

Marking |

Nibbling |

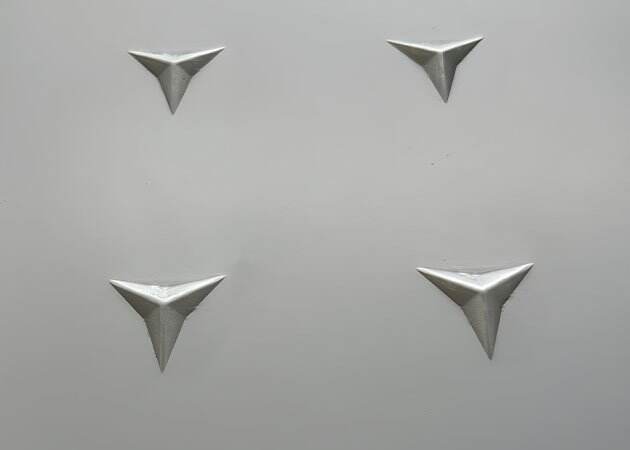

Emboss |

| Frame |  |

O-type closed integral welding press frame special for servo punch press.Holistic welding structure, stress relief from tempering treat- ment.The strong rigidity and high tonnage ensure the stable accuracy for long time, extend the service life of the machine and tools, and improve the positioning precision, reliability and durability. |

| Drive Mode |  |

Mechanical drive mode, through the main motor to drive the flywheel rotation, the use of flywheel inertia stamping, stamping control by the clutch, simple structure, low product price, stable performance, simple and convenient maintenance. |

| Full Auto Indexed Station |

Unique worm gear structure to ensure the ac- curacy of positive and negative bidirectional transmission. Single import synchronous belt drive to ensure synchronization between up and down. |

|

| Worktable |

The worktable surface with hard brush and steel ball, to lower down the noise while working and protect the surface of the sheet. Seamless worktable design to avoid collision during sheet metal movement. Folding table design, side auxiliary platform automatic fold- ing control, easy to change tooling. Aluminum edging design, side aluminum edging, protect the worktable surface from wear. Side loading auxiliary roller, easy to loading the plate. |

|

| Floatable Pneumatic Clamps |  |

The pneumatic floatable clamps reduce the deformation of the plate. The self-protection function makes no dead area for punching on sheet. The clamp automatically floats when clamping the plate, convenient for the plate clamp. Automatic unloading when the clamp returns. |

| Turret and Tooling |  |

Precision wear-resistant guide holder inlaid on turret, large machining center in pairs pro- cessed International standard Japan AMADA long guide tool, Reasonable. |

| Feeding System |  |

High-precision Feeding: X, Y-axis guides and lead screws are integrated, ensuring precise material handling. Pneumatic clamps enhance stability. |

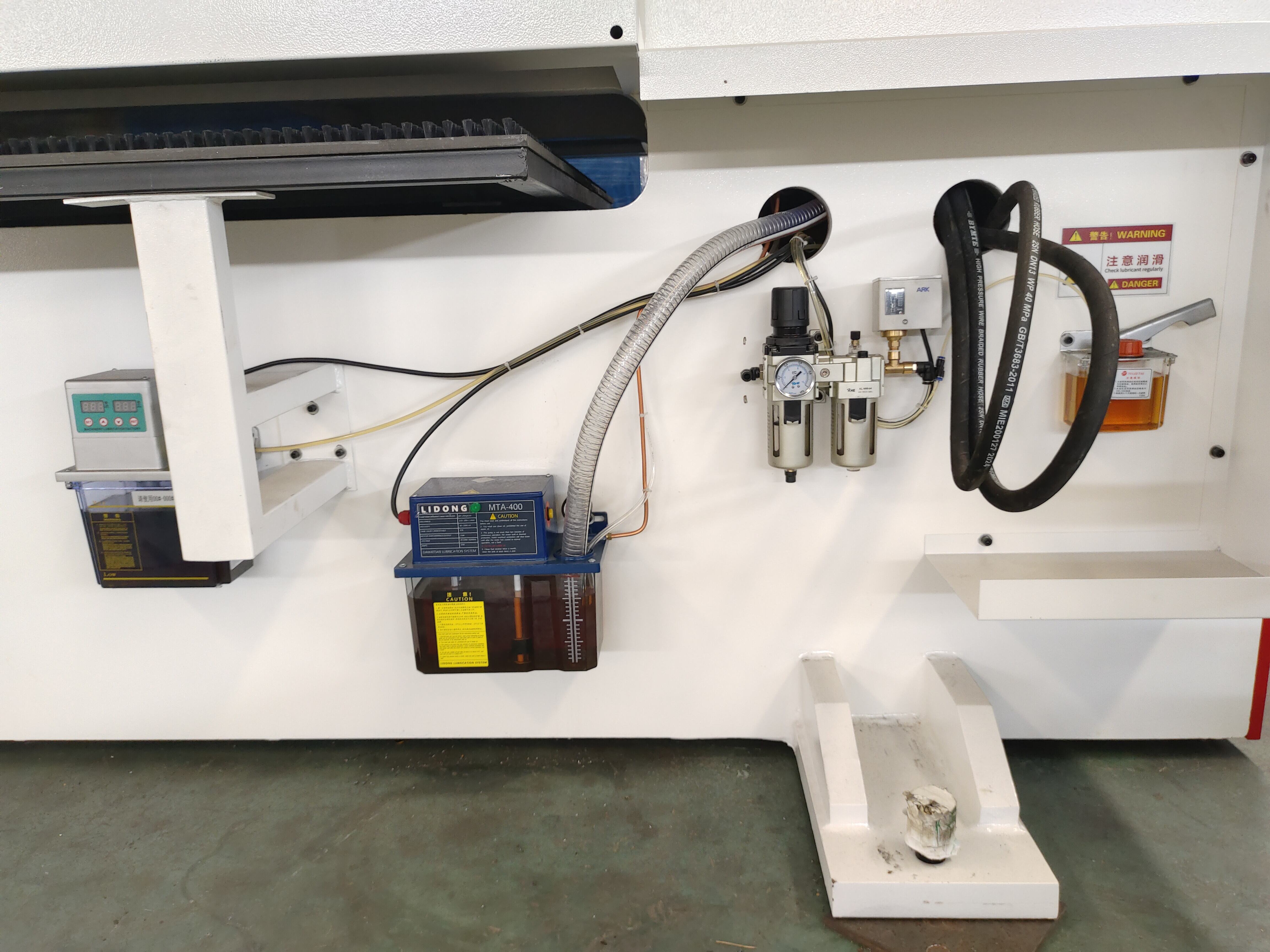

| Lubrication System |  |

Multi-point automatic lubrication ensures sufficient lubrication, reducing wear. |