Home / Products / Press Brake

Compared to traditional press brakes, CNC press brakes deliver better bending accuracy and efficiency, enabling a 30% increase in bending times within the same period.

Model:PBS/PBE 1500mm-4100mm

Controller Brand: DELEM, CYBELEC, ESA

Capabilities: 30T - 5000T

| Machine Model | bending force (KN) |

Bendable width (mm) |

Column spacing (mm) |

Open height (mm) |

Laryngeal Depth (mm) |

Cylinder stroke (mm) |

vertical board | side panel | slider | Main motor power (KW) |

Hydraulic oil weight (L) |

speed(mm/s) | Exterior Dimensions(mm) | ||||

| thicknesses(mm) | drive | neutralize | return journey | Dimensions Length | width | Height | |||||||||||

| PBS-63/1500 | 600 | 1500 | 1200 | 580 | 350 | 215 | 70 | 40 | 50 | 8.7 | 130 | 185 | 19 | 180 | 2000 | 1620 | 2470 |

| PBS-63/2100 | 600 | 2100 | 1600 | 580 | 350 | 215 | 70 | 40 | 50 | 8.7 | 170 | 185 | 19 | 180 | 2600 | 1620 | 2470 |

| PBS-63/2550 | 600 | 2550 | 2050 | 580 | 350 | 215 | 70 | 40 | 50 | 8.7 | 200 | 185 | 19 | 180 | 3150 | 1620 | 2500 |

| PBS-100/3200 | 1000 | 3200 | 2700 | 580 | 390 | 215 | 80 | 50 | 60 | 10.8 | 300 | 220 | 17 | 210 | 3720 | 1720 | 2550 |

| PBS-100/4100 | 1000 | 4100 | 3600 | 580 | 390 | 215 | 90 | 50 | 70 | 10.8 | 400 | 220 | 17 | 180 | 4620 | 1720 | 2550 |

| PBS-150/3200 | 1500 | 3200 | 2700 | 580 | 405 | 215 | 90 | 60 | 70 | 13.2 | 300 | 180 | 14 | 180 | 3780 | 1730 | 2600 |

| PBS-150/4100 | 1500 | 4100 | 3600 | 580 | 405 | 215 | 100 | 60 | 80 | 13.2 | 400 | 180 | 14 | 170 | 4680 | 1730 | 2600 |

| PBS-220/3200 | 2200 | 3200 | 2700 | 580 | 405 | 215 | 100 | 70 | 80 | 16.7 | 300 | 160 | 12 | 160 | 3830 | 1800 | 2670 |

| PBS-220/4100 | 2200 | 4100 | 3600 | 580 | 405 | 215 | 110 | 70 | 90 | 16.7 | 400 | 160 | 12 | 150 | 4730 | 1800 | 2670 |

Remarks; N is the number of axes, including Y1, Y2, X, R and other axes; V is the compensation axis (mechanical compensation)

PBS100T CNC Machine Configuration List

|

No. |

Name |

Model |

Brand |

|

|

1 |

CNC system |

DA53T |

DELEM, Netherlands |

|

|

2 |

Rear gear servo motor |

EM3G-09 |

ESTUN |

|

|

3 |

Rear gear servo drive |

ED3L-10AMA |

ESTUN |

|

|

4

|

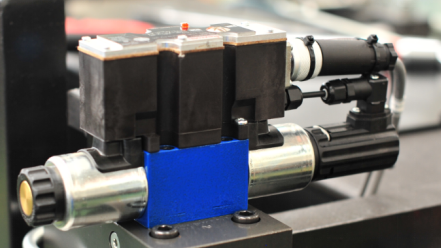

Hydraulic system Main valves

|

Electro-hydraulic servo-hydraulic valve manifold |

Bosch-Rexroth, Germany |

|

|

Synchronization control assembly

|

a.Back pressure valve |

|

||

|

b.Poppet valve |

|

|||

|

c.Proportional servo valves |

|

|||

|

Hydraulic control assembly

|

a. Cartridge valve |

|||

|

b. Pressure sensor |

|

|||

|

c. Directional valves |

|

|||

|

d. Proportional pressure reducing valves |

|

|||

|

5 |

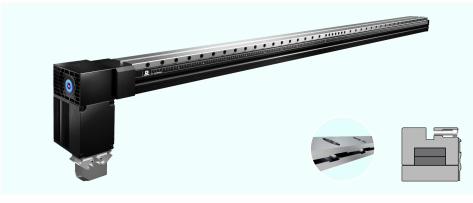

Linear guides

|

35 |

AIRTAC/SHAC |

|

|

25 |

AIRTAC/SHAC |

|||

|

6 |

Ball screw |

880/1000 |

PMI/Germany VOLLEY |

|

|

7 |

Oil pump |

LXPG1H-20 |

Bosch-Rexroth, Germany |

|

|

8 |

Cylinder Seal |

Set A full set of seals |

PARKER or SKF. |

|

|

9

|

Complete set of high pressure line

|

1.GE16 ZSR 3/4EDCF |

PARKER/ BRENNAN (USA)

|

|

|

2.GE28 LR3/4EDOMDCF |

||||

|

3. W10 ZLCF |

||||

|

4.WH10 ZSR KDSCF |

||||

|

5. WH10 ZLR KDSCF etc. |

||||

|

10 |

Couplings |

GGRMP |

SIT |

|

|

11 |

AC contactors/buttons |

LC1D, XB2B, OSM |

Schneider |

|

|

12 |

Foot switches |

HRF-HD5NX |

Korea Kaikun |

|

|

13 |

Main Servo Motor |

EMB-1ZDDRC22(10.8KW) |

ESTUN |

|

|

14 |

Main Servo Drive |

PRONET-1ZDDRC |

ESTUN |

|

|

15 |

Magnet Scale |

MPS/GVS215LC |

OPKON, Turkey |

|

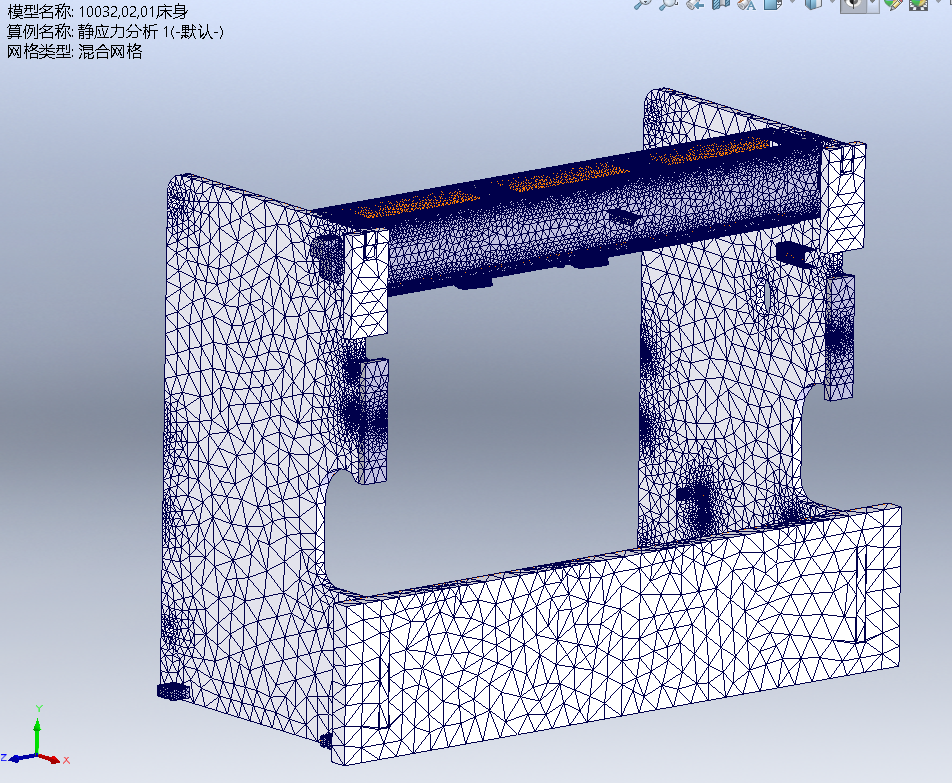

The machine body is designed through finite element optimization to ensure that the machine has high strength and rigidity when it is in use.

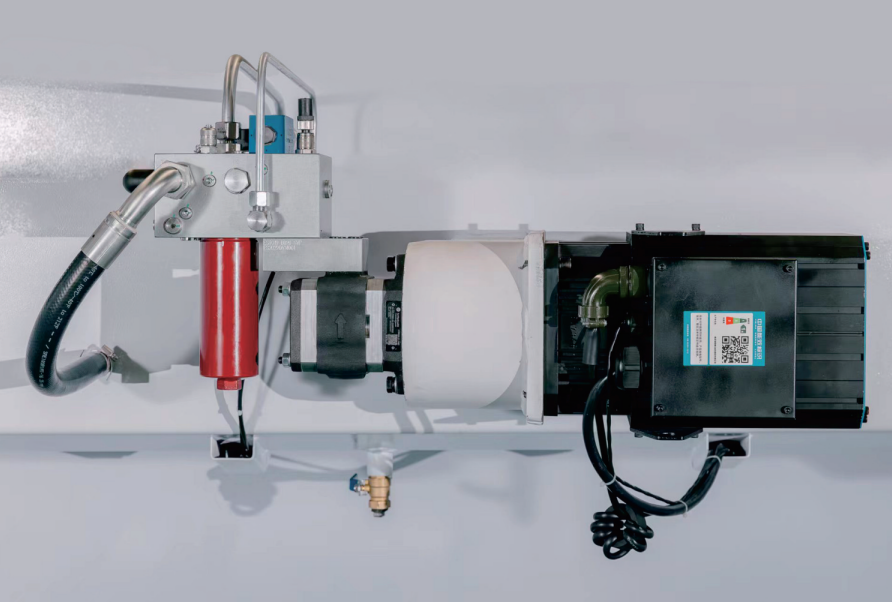

Compared with the traditional CNC bending machine, the main motor adopts servo motor, increases the pressure sensor, increases the speed of the motor, increases the flow rate of liquid filling and the displacement of the oil pump, and the Y-axis movement is softer and more efficient, and the bending efficiency is increased by 30% compared with the mainstream models in the market;

The main drive using servo motors, Y-axis speed of each state is different, greatly reducing the hydraulic overflow, thus reducing power consumption, oil temperature, saving 30-40%, because of the low oil temperature, the hydraulic oil life greatly increased;

Adopting German Rexroth full closed-loop electro-hydraulic servo synchronization control system ensures the machine tool has high stability and precision during high-speed operation.

With more reasonable closed height, throat depth, inner block distance and slide stroke, compared with the mainstream bending machine are improved, easy to bend, pick up large, complex workpiece, without additional cost can be better realized.

The whole steel plate is welded as a whole, with strong anti-vibration property.

Adopt vibration aging to eliminate the internal stress of the frame, good stability, the frame is not easy to deformation

The frame is shaped by five-sided machining center, which ensures the parallelism and perpendicularity of each mounting surface.

The throat of the frame is equipped with a “C” frame mechanism, bending accuracy and stability can be guaranteed.

Oil cylinder seals, pipe joints for the United States PARKER/SKF or the United States BRENNAN, strong sealing, long life;

Adopt the most advanced full closed-loop electro-hydraulic servo synchronization control system;

The machine tool can work continuously under the rated load, while the hydraulic system ensures no leakage and continuous stable processing with high precision;

The backstopping speed is fast and the positioning accuracy is high;

The X and R axes are driven by imported ball screws, guided by linear guide rails, and driven by digital AC servo motors with backing control function;

The stopper finger moves left and right along the linear guide rail, with fine-tuning function in the front and rear direction, easy to operate and high precision;

Adopting unique stopper structure, with one level~three level stopper finger function, expanding the range of blocking material;

The electrical components adopt foreign or joint venture brand products, which are in line with international standards, and the electric control cabinet is equipped with heat dissipation device;

The analog cable is shielded to remove electrical interference;

The sealing of the electric control cabinet meets the national standard IP54 protection level;

The foot switch adopts double foot pedals, which can be up and down, convenient and concise;

Mechanical compensation worktable design center slot and flat installation of universal;

Adopt the structure of dense point position oblique wedge compensation, to meet the angular accuracy requirements of full-length workpiece bending.

Standard with integrated gear motor, aluminum alloy baffle and scale;

Compensation closed-loop control, high control accuracy, compensation amount is automatically calculated and set by the CNC system to ensure the consistency of the full-length bending angle;

Netherlands DELEM company DA53T numerical control system

1, 10.1” high resolution true color TFT display;

2, Maximum four-axis control (Y1, Y2, X, R axis);

3, 266MHZ processor ;

4, internal storage capacity 1 GB;

5, USB storage interface, RS232 interface;

6, mold library, 30 upper mold, 30 lower mold;

7, built-in programmable PLC, stable and reliable, through the logic can save hardware wiring;

8, one-page parameter quick programming, navigation shortcut keys;

9, table deflection compensation is automatically calculated;

10, standard data programming, graphic programming optional, support for large arc, pressure bottom bending;

11, emergency stop switch panel;

12, automatic calculation of bending pressure, mold safety zone;

13, online running analysis tools;

14, Angle correction database;

15, system diagnostic function;

16, Delem-Linux operating platform to ensure the stability of system operation, support for instantaneous shutdown;

17, standard offline programming software;

18, optional dual-machine linkage function;

19, diagnostic functions, can monitor the IO digital, monitoring analog, the status of each axis;

20、Automatic totalization of machine working time and bending times;