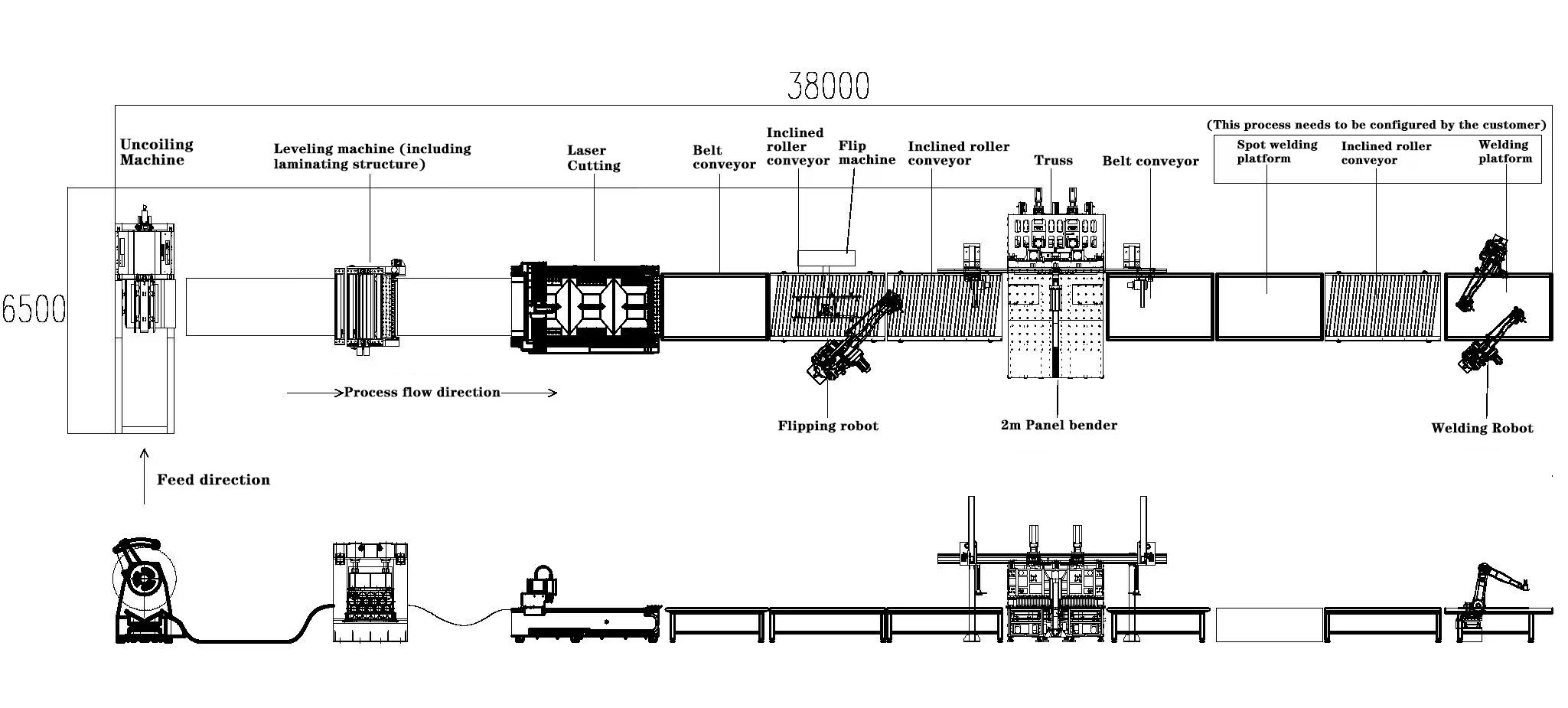

1.STON’s sheet metal production line offers an all-in-one solution, integrating uncoiling, leveling, laser cutting, punching, bending, and welding into one efficient system.

2.This production line covers every stage of sheet metal processing, meeting the demands of high-efficiency, large-scale production.

3.Various combinations, laser cutting unit can form an automated production line with press brake, panel bender, CNC turret punch press

4.Provide free pre-sales review and technical solutions based on product drawings

5.Various automation options available, such as trusses or robotic arms

Customized, the parameters of the production line are determined according to the customer's steel coil size, weight, plate material and thickness as well as product drawings.

Production line plan structure diagram(Take a 2m panel bender as an example)

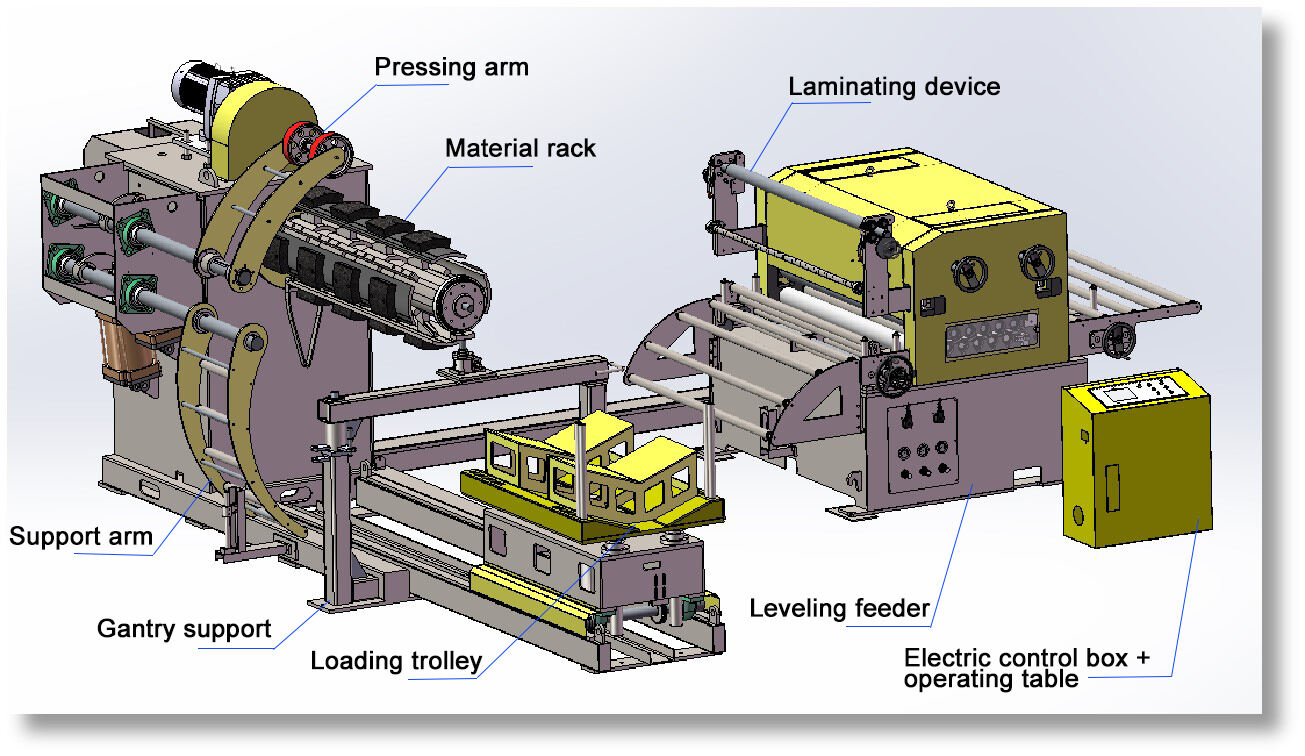

1.Uncoiling and Leveling Module

|

Uncoiling device unwinding rack |

Leveling Machine |

The leveling equipment can straighten uneven sheet metal plates. Through the precise coordination of multiple sets of rollers, it can effectively eliminate the wavy and twisted defects on the surface of the plate, ensure that the flatness of the plate reaches high-precision standards, and lay a good foundation for subsequent processing.

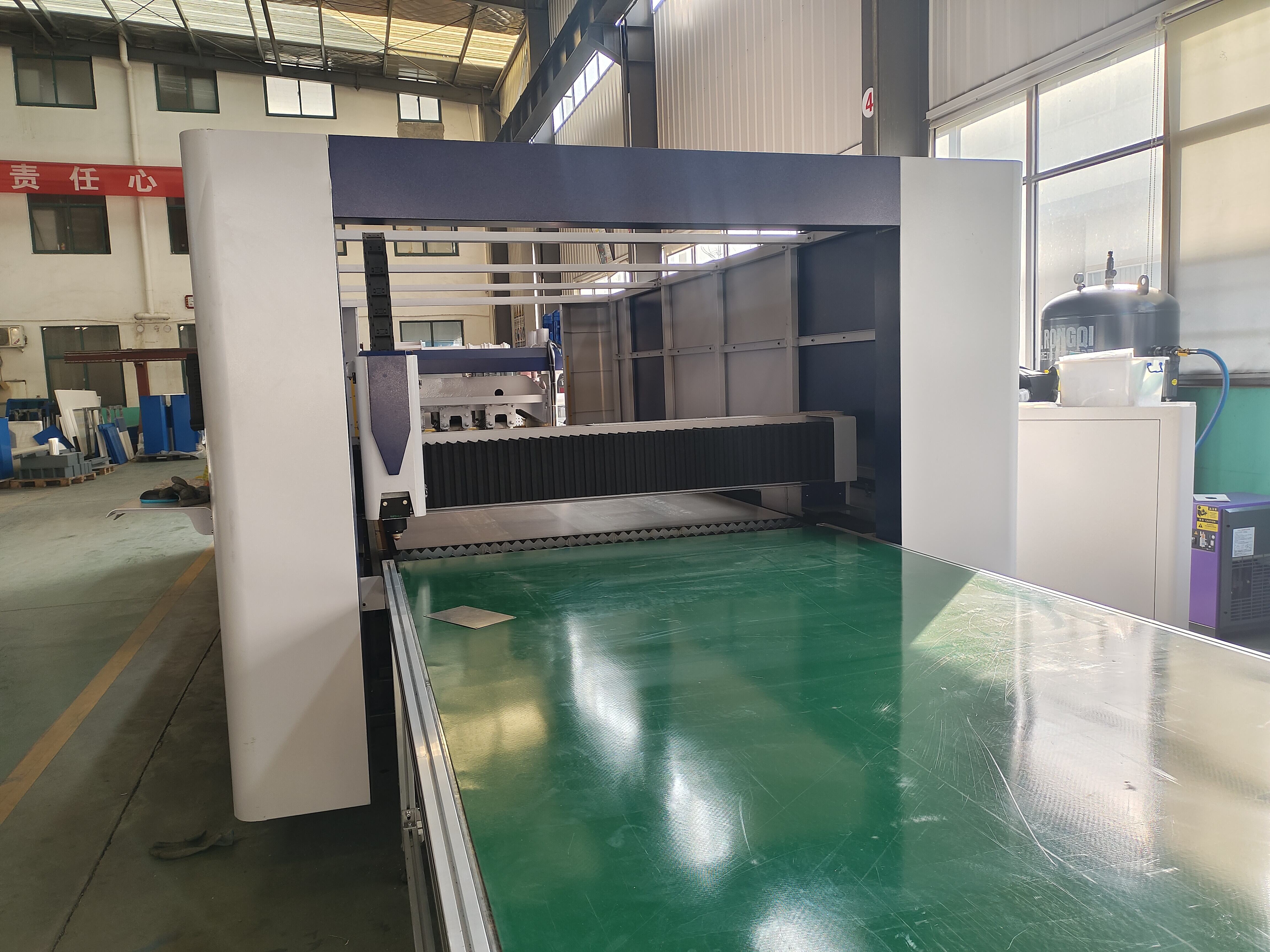

2.Laser Cutting and Blanking Module

The leveled sheet enters the laser cutting unit. The unit is equipped with advanced laser cutting technology and can accurately cut sheet metal according to the pre-set cutting program. Whether it is complex geometric figures or part contours with fine structures, they can be separated quickly and accurately with the high energy density of the laser, and the cutting edges are smooth and the accuracy can reach the millimeter level or even higher. At the same time, the robot system works closely with the laser cutting unit. With its flexible robotic arm and precise grasping and positioning capabilities, it can quickly and stably complete the loading and unloading operations of the sheet, greatly improving the production efficiency of the cutting process.

|

|

3.Bending and Forming Module

The cut sheet metal parts are then sent to the electro-hydraulic bending machine by the robot. With its powerful hydraulic drive system and precise control system, the electro-hydraulic bending machine can bend sheet metal parts at multiple angles and curvatures according to product requirements. Whether it is a simple right-angle bend or a complex arc or multi-fold shape, precise forming can be achieved by precisely controlling the bending angle and force.

For more complex and high-precision bending needs, the flexible bending center plays a key role. It integrates advanced CNC technology and intelligent algorithms, and can quickly switch between different bending molds and processing parameters to achieve efficient bending processing of sheet metal parts of various specifications and shapes. Throughout the production process, the robot continues to act as a "bridge" for material transmission, flexibly transporting sheet metal parts between various equipment to ensure seamless and efficient production processes.

|

|

4.Welding and Assembly Module

The bent sheet metal parts are transferred by the robot to the manipulator welding forming station. The manipulator welding forming equipment is equipped with a high-precision welding system and a visual tracking system, which can automatically select the appropriate welding process (such as argon arc welding, spot welding, etc.) and welding parameters according to the welding requirements of the sheet metal parts. During the welding process, the visual tracking system monitors the weld position in real time and guides the manipulator to accurately complete the welding operation, ensuring that the weld is uniform and firm, and the welding quality is stable and reliable.

During the entire automated production process, the truss, robotic arm and flexible bending center realize real-time data interaction and sharing through industrial Ethernet and other communication technologies, and are uniformly dispatched and managed by the central control system. The central control system dynamically optimizes the production process based on multi-dimensional data such as production plan, equipment status, material information, etc., and reasonably arranges the work tasks of each equipment to ensure the efficient and stable operation of the entire production process, which greatly improves the automation level and production efficiency of sheet metal processing production.

5.Material Handling and Automation Module

There are two forms of automated loading and unloading: truss and robotic arm

(1)The robotic arm grabs the sheet metal parts that have been processed by leveling, laser cutting and other preliminary processes from the processing area with its flexible joints and precise positioning capabilities. The grabbing device at the end of the robotic arm can be adaptively adjusted according to the shape and size of the sheet metal parts to ensure a smooth and reliable grabbing process and avoid damage to the workpiece. After grabbing, the robotic arm quickly transfers the sheet metal parts to the starting position of the truss conveyor track.

(2)A more economical choice. With its stable structure and strong load capacity, the truss conveys the sheet metal parts to the flexible bending center along the preset track. The truss is equipped with a high-precision servo drive system, which can achieve fast and stable linear motion, and can flexibly adjust the running speed and position according to production needs to ensure that the sheet metal parts are accurately delivered to the loading station of the flexible bending center.