Home / Products / Press Brake

Bending Length:400~3200mm

Tonnage:6~100T

Pure electricity does not require hydraulic oil and only requires 1-2 kWh of electricity per hour

Compared with hydraulic press brakes, it saves 30%-50% of electricity and reduces standby energy consumption

No risk of hydraulic oil contamination, low operating noise

Equipped with fault self-diagnosis function, easy to quickly troubleshoot problems

Support digital programming, can preset a variety of bending process parameters, easy to operate

No complicated hydraulic system pipelines, avoiding oil leakage, hydraulic oil aging and other problems, reducing maintenance frequency and cost

Main parameters of pure electric servo CNC press brake

| No. | Name | Unit | 25/1000 | 40/1600 | 60/2000 | |

| 1 | CNC System | / | Delem system from the Netherlands controls the Y1, Y2, X, R, Z1, Z2 axes | |||

| 2 | Maximum bending tonnage | T | 25 | 40 | 60 | |

| 3 | Longest bending length | mm | 1000 | 1600 | 2000 | |

| 4 | Y-axis motor power | Kw | 4.4*2 | 7.5*2 | 7.5*2 | |

| 5 | X/R-axis motor power | Kw | 0.75*2 | 0.75*2 | 0.75*2 | |

| 6 | Z-axis motor power | Kw | 0.4*2 | 0.4*2 | 0.4*2 | |

| 7 | Axis travel | Cylinder travel | mm | 150 | 150 | 180 |

| X-axis travel | mm | 500 | 500 | 500 | ||

| R-axis travel | mm | 140 | 140 | 140 | ||

| Z-axis travel | mm | 400 | 600 | 600 | ||

| 8 | Accuracy value | Y-axis repeatability accuracy | mm/s | ±0.01 | ±0.01 | ±0.01 |

| X-axis repeatability accuracy | mm/s | ±0.02 | ±0.02 | ±0.02 | ||

| R-axis positioning accuracy | mm/s | ±0.1 | ±0.1 | ±0.1 | ||

| Z-axis positioning accuracy | mm/s | ±0.1 | ±0.1 | ±0.1 | ||

| 9 | Efficiency value | Y-axis down speed | mm | 200 | 240 | 140 |

| Y-axis forward speed | mm | 40 | 40 | 40 | ||

| Y-axis return speed | mm | 200 | 240 | 140 | ||

| X-axis forward speed | mm | 500 | 500 | 500 | ||

| R-axis forward accuracy | mm | 200 | 200 | 200 | ||

| Z-axis forward speed | mm | 400 | 400 | 400 | ||

| 10 | Distance between columns | mm | 900 | 1380 | 1700 | |

| 11 | Throat depth | mm | 145 | 300 | 300 | |

| 12 | Opening height | mm | 420 | 420 | 470 | |

| 13 | Machine weight | kg | 1200 | 2500 | 3600 | |

| 14 | Dimensions | mm |

L×W×H 1200*1050*2150 |

L×W×H 1700*1300*2430 |

L×W×H 2200*1360*2550 |

|

PBE series standard configuration(Can be changed according to customer needs)

| No. | Name | PBE series standard configuration(6-100T) | Brand |

| 1 | Machine structure | Upward action | STON |

| 2 | Number of controlled axes |

≤35T,3 Axis ≥40T,4+1 Axis |

|

| 3 | CNC system | SL-100-PS | Newland |

| 4 | Main lead screw | Heavy-duty ground screw | Nanjing Craft/Hanjiang |

| 5 | Reducer | Planetary reducer | Newland |

| 6 | Motor | Servo | China-Japan Wistron |

| 7 | Compensation | Mechanical compensation | STON |

| 8 | Fixture | Double-sided quick clip | STON |

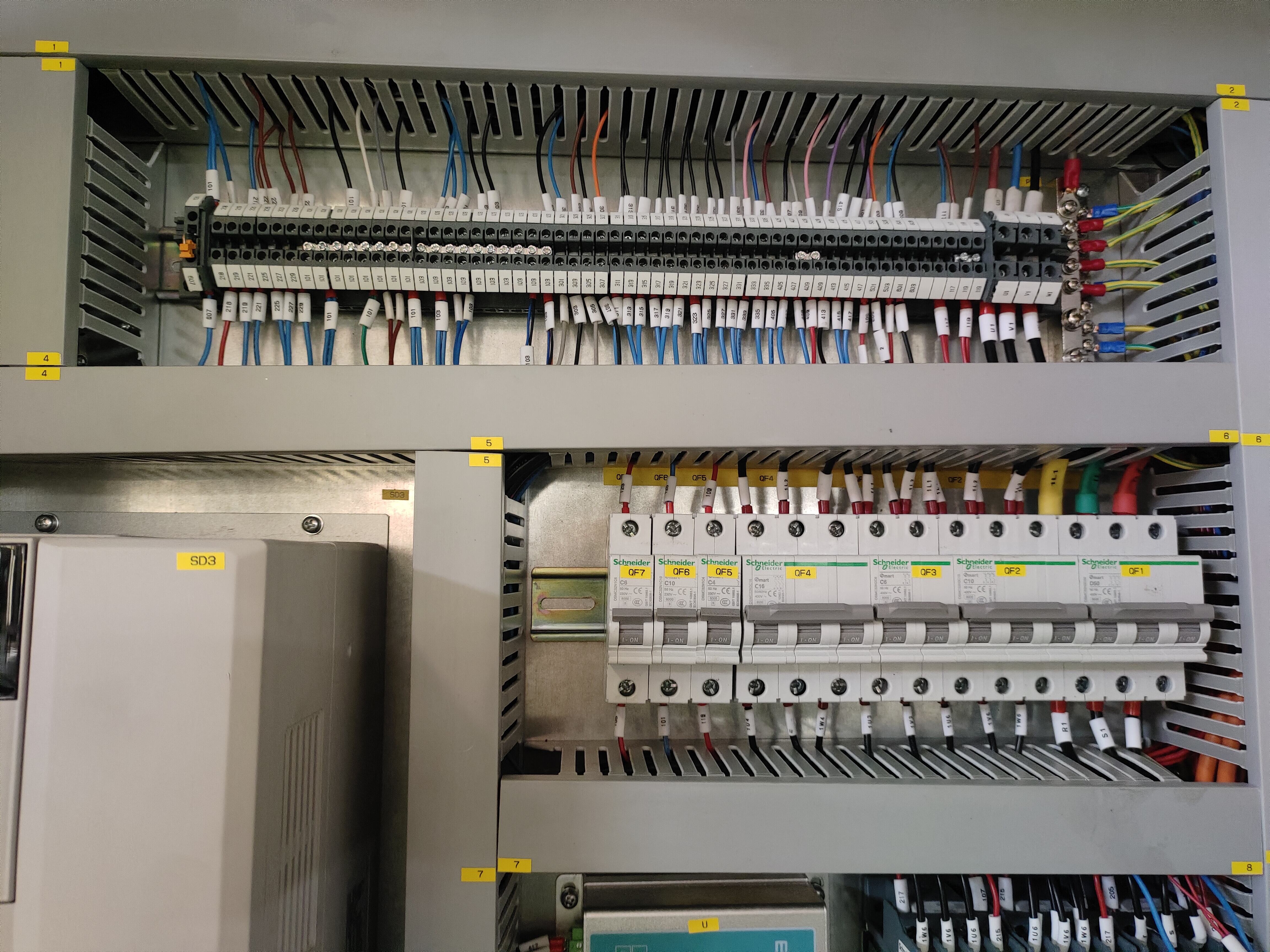

| 9 | Electrical components | Scheider | France |

| 10 | Foot switch | Double pedal type | ENCHI |

| 11 | Voltage | 380V-50Hz-3P | |

| 12 | Protection | Fully enclosed | STON |

| 13 | Front support rack | Standard+Linear Guide | STON |

|

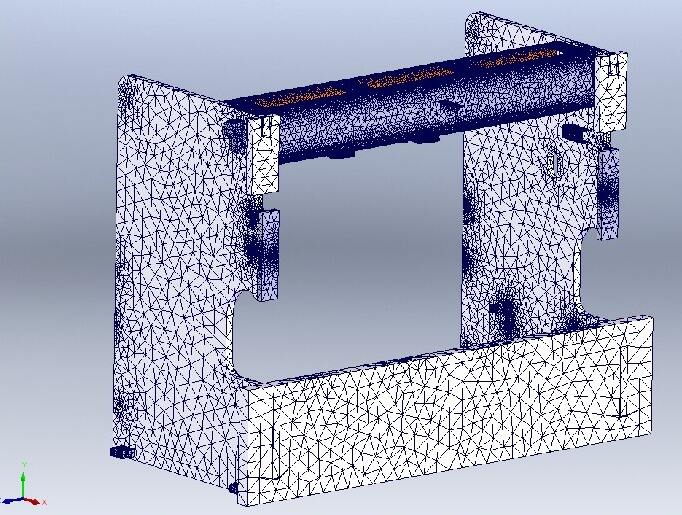

Fuselage structure The fuselage structure is optimized through finite element design to minimize the impact of bending deformation on workpiece quality. With more reasonable closing height, throat depth, inner stop distance and slider stroke, it is convenient to bend and take large and complex workpieces, which can be better achieved without additional cost. |

|

Bending And Positioning Avoidance Die Each model of our bending machine has sufficient space for sheet metal to avoid interference. It can produce all kinds of complex sheet metal parts without worries for users. The slider stroke space of the bending machine is large, and the upper die with a height of 180mm-210mm can be clamped according to different models. |

|

|

Control System 15.6-inch embedded all-in-one computer (including touch screen),high resolution 1920×1080; Linux embedded operating system; developed based on American TI (Texas Instruments) chips; USB peripheral interface |

|

Schneider Electrical Components

|

|

|

Back Gauge Structure The crossbeam is processed with high-quality carbon steel, and the overall structural design is simple, compact, and stable, resulting in fast speed and high accuracy. The standard configuration for the rear material blocking of this machine is X and Y axes, with 2 adjustable blocking fingers. |